0. A Review on the Recycling of 3D-Printed Concrete Materials in the Context of Carbon Neutrality

1. Introduction: The Imperative of Sustainable Construction and 3D Printing

The global construction industry is a major contributor to environmental degradation, characterized by significant greenhouse gas emissions, extensive material consumption, and substantial waste generation . This sector's environmental footprint necessitates a critical shift towards sustainable practices to achieve carbon neutrality and mitigate its profound impact. A primary concern is the production of conventional construction materials, particularly cement, which is integral to concrete, the most widely used building material globally . The cement industry alone contributes approximately 8% of total global carbon emissions, accounting for an estimated 1.7 billion metric tons of CO2 emissions in 2022 . This issue is compounded by projected increases in concrete demand, underscoring the urgent need for sustainable alternatives . Furthermore, the reliance on natural aggregates leads to resource depletion and ecological damage .

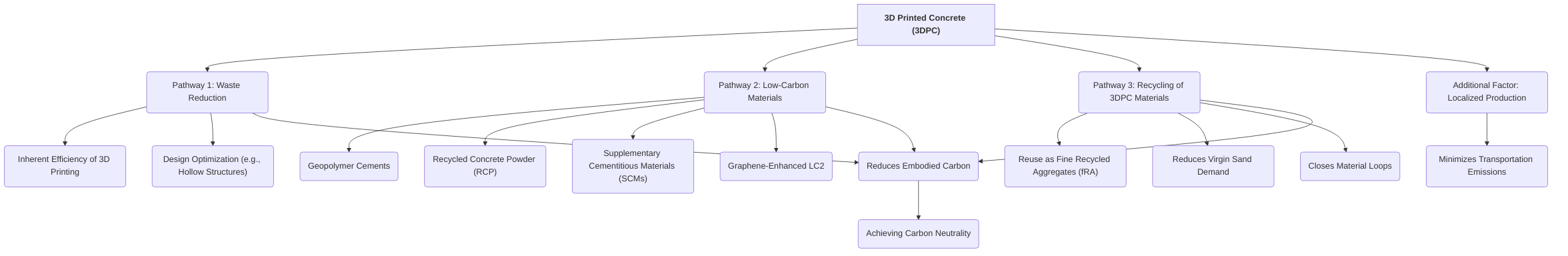

Three-dimensional printed concrete (3DPC) emerges as a promising solution to these challenges, offering significant opportunities for sustainable construction through additive manufacturing principles . This technology inherently reduces material usage and waste by enabling precise, layer-by-layer fabrication and the creation of optimized, hollow structures that minimize material consumption compared to conventional methods . Studies indicate that 3DPC can reduce material waste by up to 90%, and its localized production capabilities further decrease transportation emissions . Advancements in low-carbon concrete inks, such as those incorporating graphene with limestone and calcined clay cement (LC2), or fly ash and biomass waste, further enhance 3DPC's sustainability profile . Despite these advantages, challenges persist, particularly concerning the high cement content and stringent aggregate quality requirements for printable mixtures . Therefore, future efforts are focused on integrating recycled aggregates and powders and adopting circular design principles like Design for Disassembly (DfD) to ensure comprehensive lifecycle sustainability for 3DPC structures . This review will specifically focus on the recycling of 3D-printed concrete materials within a carbon neutrality framework, outlining the structure and scope of this survey.

1.1 Global Construction's Environmental Footprint and the Need for Carbon Neutrality

The global construction industry is widely recognized as a significant contributor to environmental degradation, primarily due to its substantial consumption of resources and the considerable greenhouse gas emissions associated with its processes and materials . This sector's environmental burden necessitates a critical shift towards more sustainable practices to mitigate its impact .

A major component of this environmental footprint stems from the production of conventional construction materials, particularly concrete. Concrete, being the most utilized building material globally, relies heavily on cement, whose production is a principal source of carbon dioxide (CO2) emissions . The cement industry alone accounted for an estimated 1.7 billion metric tons of CO2 emissions in 2022 , contributing approximately 8% of total global carbon emissions . This high contribution is exacerbated by the projected increase in concrete demand, from 4.4 billion tons to an estimated 5.5 billion tons by 2050 .

Beyond emissions, the construction sector's reliance on natural aggregates also poses a significant environmental challenge through resource depletion . The extensive extraction of these raw materials contributes to habitat destruction, landscape alteration, and biodiversity loss. Addressing these multifaceted environmental issues is crucial for achieving carbon neutrality targets and fostering a truly sustainable built environment. The imperative to integrate sustainable building materials and processes is thus pressing, guiding the industry towards innovative solutions that minimize its ecological impact .

1.2 Introduction to 3D Printed Concrete (3DPC) and its Sustainability Potential

Three-dimensional printed concrete (3DPC) represents a paradigm shift in construction, leveraging additive manufacturing principles to fabricate structures layer by layer . This innovative technology offers significant benefits, particularly in enhancing material efficiency and reducing carbon emissions within the construction sector . The inherent precision of 3DPC allows for the creation of intricate designs, including hollow structures, which substantially reduce material consumption compared to conventional construction methods .

Traditional construction often involves extensive on-site cutting and shaping, leading to considerable material waste. In contrast, 3DPC's additive nature enables material deposition directly at the point of use, effectively minimizing waste generation . Studies have indicated that 3D concrete printing can reduce material waste by up to 90% . This waste reduction, coupled with the potential for localized production, also contributes to decreased transportation emissions and a lower overall environmental impact .

While there is a consensus on 3DPC's material efficiency, different studies emphasize various aspects of its waste reduction capabilities. For instance, some research highlights how the optimization of structural design through 3DPC leads directly to reduced material usage and waste . This is further supported by the ability to create complex geometries like hollow structures, which fundamentally minimizes material consumption . Furthermore, the development of low-carbon concrete inks and materials, such as graphene combined with limestone and calcined clay cement (LC2), or the incorporation of fly ash and biomass waste, signifies a direct effort to further improve the sustainability profile of 3DPC beyond just waste reduction . Companies like CyBe Construction have also pioneered eco-friendly materials that result in up to 32% fewer CO2 emissions, reinforcing the inherent lower carbon footprint of 3DPC due to reduced material usage and waste .

Despite these inherent advantages, challenges remain, particularly concerning the high cement content typically required for printable mixtures and the strict requirements for aggregate quality in 3DPC . Therefore, while the initial sustainability benefits of 3DPC are significant in terms of material efficiency and waste reduction, the broader sustainability agenda also necessitates addressing the environmental impact of its material composition. This is leading to increased focus on incorporating recycled aggregates and powders and integrating circular design principles like Design for Disassembly (DfD) to ensure sustainability throughout the entire lifecycle of 3DPC structures .

2. The Environmental Imperative: Challenges and Opportunities for Recycling in 3DPC

The global construction industry, heavily reliant on conventional concrete, faces substantial environmental challenges, primarily stemming from significant waste generation and high carbon emissions. Traditional concrete production, particularly cement manufacturing, is a major contributor to global CO2 emissions, accounting for approximately 1.7 billion metric tons in 2022 . Annually, around 50 billion tonnes of sand are consumed worldwide, an extraction process that is energy-intensive and environmentally damaging .

| Waste Source | Annual RFA Generation (EU Countries) | Disposal Method | Impact |

|---|---|---|---|

| Construction & Demolition Waste (CDW) | ~65 Million Tonnes | Landfilled or "Down-cycled" (due to impurities) | Resource Depletion, Landfill Burden |

| Virgin Sand Consumption (EU Countries) | 54 Million Tonnes | N/A | Habitat Destruction, Landscape Alteration |

Construction and Demolition Waste (CDW) represents one of the largest waste streams globally, with European countries alone generating an estimated 65 million tonnes of Recycled Fine Aggregates (RFA) annually . Despite this, a substantial portion of RFA is landfilled or "down-cycled" due to impurities and stringent quality standards, contrasting sharply with the continuous demand for virgin sand .

In contrast, 3D Concrete Printing (3DPC) presents a transformative opportunity to mitigate these environmental impacts. 3DPC inherently minimizes waste through precise material deposition, offering up to a 90% reduction in material waste compared to conventional construction methods . This precision not only conserves resources but also opens avenues for incorporating low-carbon materials and recycled components .

However, recycling 3DPC materials introduces unique complexities that differentiate it from conventional concrete recycling. While traditional concrete recycling primarily focuses on valorizing CDW into recycled aggregates (RA), 3DPC generates specific waste streams such as failed prints, excess material from printhead purging, or imperfect layers . Reincorporating these specific 3DPC production wastes directly into new mixes presents a distinct challenge and opportunity for a more closed-loop system. The variability in recycled aggregate properties, whether from CDW or failed 3DPC prints, significantly impacts the fresh and hardened properties of the new mix, affecting printability, green strength, setting time, and mechanical properties, particularly at higher replacement rates (e.g., above 20 vol%) . This inconsistency often renders recycled aggregates unsuitable for mass production requiring standardized materials .

Beyond technical considerations, regulatory, economic, and social dimensions also pose hurdles. The absence of standardized regulations for recycled 3DPC materials impedes consistent application and market adoption. Economically, the cost-effectiveness of collecting, processing, and reincorporating 3DPC waste needs further investigation. Socially, fostering greater acceptance and demand for structures built with recycled 3DPC is crucial. Future solutions for 3DPC waste valorization can draw insights from urban planning to establish efficient collection and processing centers, from environmental policy to develop incentives and regulations for material circularity, and from business management to guide the development of viable circular business models, such as those that reincorporate "returned products" into the material stream . Research gaps remain in the systematic study of directly recycling failed 3D-printed components, including comprehensive analysis of processing methods, material characterization, and performance limitations.

2.1 The Environmental Impact of Conventional Concrete Waste

The widespread reliance on concrete as the primary building material globally presents significant environmental challenges, particularly concerning waste generation and resource depletion . Annually, approximately 50 billion tonnes of sand are consumed worldwide, an extraction process that demands substantial energy and inflicts considerable environmental damage. This extensive demand for natural resources underscores the critical need for alternative materials and practices within a circular economy framework .

A major environmental concern stems from Construction and Demolition Waste (CDW), which constitutes one of the most substantial material flows globally . Specifically, within five European countries (France, Germany, UK, Netherlands, Belgium), an estimated 65 million tonnes of Recycled Fine Aggregates (RFA) are generated annually from demolition waste . Despite the vast quantities generated, a significant portion of this RFA is currently relegated to landfills, contributing to landfill burden and resource depletion .

Current waste management practices for CDW face considerable hurdles, impeding the widespread adoption of recycling and recovery products. Recycled fine aggregates, for instance, are often "down-cycled" or landfilled due to the presence of impurities and the stringent quality standards required for new construction materials . This scenario contrasts sharply with the annual consumption of 54 million tonnes of natural sand in the same European countries, highlighting a missed opportunity to conserve natural resources by utilizing readily available RFA . While ambitious goals for CDW management have been established by entities like the EU, the market uptake of recycled products remains insufficient, underscoring the challenges in transforming waste into valuable resources . The environmental impact extends beyond waste disposal, as cement production, a key component of concrete, was responsible for approximately 1.7 billion metric tons of carbon dioxide emissions in 2022 .

2.2 Specific Challenges of Recycling 3DPC Materials

Recycling 3D-printed concrete (3DPC) materials presents distinct challenges compared to conventional concrete due to specific material properties and waste generation patterns inherent to the additive manufacturing process. Unlike traditional concrete production, 3DPC processes can generate unique waste streams, such as failed prints and excess material from printhead purging or layer imperfections. While conventional concrete recycling primarily focuses on the valorization of construction and demolition waste (CDW) into recycled aggregates (RA), 3DPC recycling must also consider the direct reincorporation of specific 3DPC production waste.

A critical distinction lies in the origin of recycled materials. Research on 3DPC often investigates the use of recycled demolition waste as aggregates. For instance, the Recycl3D project explicitly targets the under-utilization of fine recycled aggregates (fRA) from CDW, aiming to valorize them in higher-grade 3D printing applications . Similarly, Hyperion Robotics’ system incorporates end-of-cycle industrial materials, including demolition waste, to reduce embodied CO2 emissions and costs . However, challenges persist with CDW, as impurities and stringent standards often prevent its direct recycling back into high-performance concrete without significant processing .

Utilizing RA in 3DPC mixes can reduce concrete strength and increase anisotropy, particularly at higher replacement rates (above 20 vol%), which adversely affects printability, green strength, setting time, and mechanical properties in initial curing stages . This contrasts with the direct recycling of failed 3D prints, which conceptually offers a more closed-loop system for managing specific 3DPC waste streams.

A significant research gap exists in the systematic study of directly recycling failed 3D-printed components. While some studies implicitly touch upon this by converting 3DPC waste into fRA , comprehensive analysis of processing methods, material characterization, and performance limitations of directly recycled 3DPC waste is limited. For instance, the "returned products" concept in a circular business model for 3DPC suggests direct recycling of failed or end-of-life 3D-printed components into recycled fine aggregates (RFA), yet the consistency in grade and composition of RFA from different sources remains a challenge, demanding continuous characterization and adjustment of mortar formulas . The ease of separability of materials is crucial for reusability and recyclability, as highlighted by a case study that excluded reinforcement from 3DCP vaults to enable integration of production waste as crushed concrete filler .

Current technical hurdles in achieving consistent quality and performance of recycled 3DPC are multifaceted. The variability in recycled aggregate properties, whether from CDW or failed 3DPC prints, significantly impacts the fresh and hardened properties of the new mix. For example, incorporating fRA from waste 3DPC negatively affects printability, green strength, setting time, and mechanical properties, especially at higher replacement rates . This inconsistency makes recycled aggregates unsuitable for mass production requiring standardized materials .

Beyond technical aspects, regulatory, economic, and social dimensions also pose challenges. The lack of standardized regulations for recycled 3DPC materials hinders market uptake and consistent application. Economically, the cost-effectiveness of collecting, processing, and reincorporating 3DPC waste, especially from direct prints, needs further exploration. Socially, there is a need for greater acceptance and demand for structures built with recycled 3DPC. Insights from urban planning could inform the establishment of efficient collection and processing centers for 3DPC waste. Environmental policy can provide incentives and regulations for material circularity in 3DPC. Business management principles can guide the development of viable circular business models, such as those that reincorporate "returned products" into the material stream .

The following comparative matrix details the processing methods, material characterization challenges, and performance limitations of recycled 3DPC from different studies:

Comparative Matrix of Recycled 3DPC Studies

| Study Bibkey | Recycled Material Source | Processing Method | Material Characterization Challenges | Performance Limitations |

|---|---|---|---|---|

| Recycled aggregates (RA) | Not explicitly detailed | Not explicitly detailed | Reduced strength, increased anisotropy | |

| Fine recycled aggregates (fRA) from waste 3DPC | Processing of waste 3DPC into fRA | Not explicitly detailed | Adverse effects on printability window, green strength, setting time, mechanical properties (especially at >20 vol% replacement) | |

| Recycled fine aggregates (RFA) from CDW and "returned products" | Mixture Proportioning Method (MPM) | Inconsistency in grade and composition of RFA | Unsuitable for mass production requiring standardized materials (though suitable for UMG furniture) | |

| Fine recycled aggregates (fRA) from CDW | Not explicitly detailed, focuses on valorization into higher-grade applications | Predicting mechanical, durability, and service-life properties | Under-utilization and low market uptake | |

| Recycled concrete powder (RCP) | Not explicitly detailed | Not explicitly detailed | Affects fresh and hardened properties (details implicit to RCP's use as cement replacement) | |

| Crushed concrete filler (production waste from 3DCP vaults) | Crushing | Not explicitly detailed | Requirement to exclude reinforcement for circularity | |

| Demolition waste processed into fine aggregate | Processing into fine aggregate | Impurities | Often cannot be recycled back into concrete due to stringent standards | |

| Blast furnace slag, fly ash, mining tailings, demolition waste | Not explicitly detailed (implied incorporation into 3D printing system) | Not explicitly detailed | Not a limitation, rather an advantage; leads to significant cost savings and CO2 reduction |

3. Circular Economy Principles and Recycling Strategies for 3D-Printed Concrete Materials

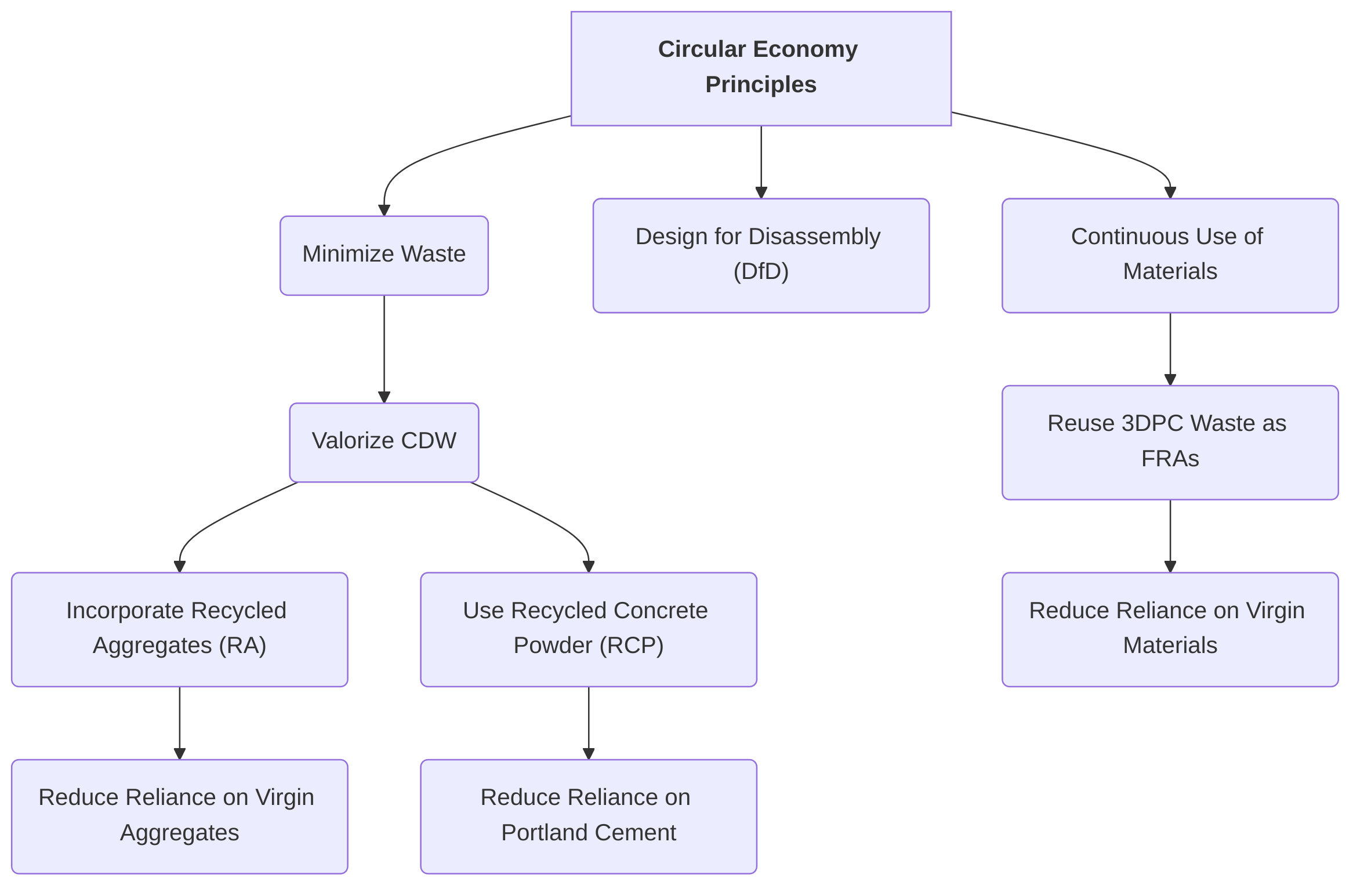

The construction industry's shift towards a circular economy (CE) paradigm is crucial for sustainability, moving away from the linear "take-make-waste" model. This transition prioritizes the continuous use of materials and energy, minimizing waste and conserving resources . In this context, 3D-printed concrete (3DPC) emerges as a highly compatible technology, offering inherent advantages for implementing CE principles due to its precise material deposition, reduced waste generation, and design flexibility .

A key enabler of CE in 3DPC is Design for Disassembly (DfD), a strategy that mandates reversible construction methods to facilitate easy separation and retrieval of components for future reuse or recycling . This approach directly contributes to CE principles by mitigating waste and reducing the demand for virgin resources. For example, 3DPC elements can be designed with mechanical, accessible, and separable connections, while avoiding chemical adhesives that hinder material recovery . The modularity often inherent in 3D-printed designs further supports DfD, making deconstruction and material recovery more efficient .

Beyond DfD, the incorporation of recycled content is a fundamental approach to integrating CE principles into 3DPC. This primarily involves valorizing construction and demolition waste (CDW) by using recycled aggregates (RA) and recycled concrete powder (RCP) in concrete mixes . This not only addresses waste management challenges but also conserves natural resources and significantly reduces embodied carbon emissions . For instance, the Recycl3D project explicitly aims to improve the recovery and recycling of fine recycled aggregates (fRA) from CDW for higher-grade 3DPC structures, thereby enhancing material efficiency within the circular economy value chain . Similarly, substituting cement with recycled concrete powder or local demolition waste for sand in 3DPC mixes exemplifies the efforts to reduce environmental footprints and meet the increasing demand for sustainable alternatives .

The recycling processes for 3D-printed concrete typically involve crushing and sieving waste 3DPC to produce fine recycled aggregates (fRA), which can then substitute cement or virgin aggregates in new mixes . However, a primary challenge lies in balancing environmental benefits with the need to maintain mechanical and rheological performance. High replacement rates of recycled materials can negatively impact properties such as printability, green strength, setting time, and mechanical strength, necessitating careful mix design and material characterization . Furthermore, the unique layered structure and material composition of 3DPC can influence its recyclability compared to traditional concrete, potentially requiring specific processing methods to ensure consistent quality of recycled products.

The implementation of circular economy principles also drives the development of innovative business models for 3DPC. Models focusing on localized production of urban, memorial, and garden (UMG) furniture from recycled fine aggregates (RFA) sourced from waste management companies demonstrate a closed-loop system for demolition waste . These models diversify income streams through direct sales, services, and even "product-as-a-service" approaches, while emphasizing localism to minimize transportation costs and carbon emissions. However, practical challenges include ensuring consistent availability and quality of RFA, securing market acceptance, and developing robust legal and operational frameworks for leasing models .

In summary, 3DPC aligns strongly with circular economy principles through waste reduction, material valorization, and DfD strategies. While significant progress has been made in incorporating recycled aggregates and powders, challenges remain in optimizing material properties for diverse applications and ensuring long-term durability. Future research should focus on comprehensive long-term performance assessments, standardized processing methods for various recycled materials, and the development of robust business models to accelerate the widespread adoption of circular 3DPC in the construction industry.

3.1 Circular Economy Principles for 3DPC

The circular economy (CE) represents a paradigm shift from the traditional linear "take-make-waste" model to one that prioritizes keeping materials and energy in continuous use, thereby minimizing waste . In the context of the built environment, key CE principles encompass strategies such as refitting, refurbishing, reusing, remanufacturing, and recycling, necessitating a design approach that considers a building's entire life cycle, including its end-of-life .

Additive manufacturing, specifically 3D Concrete Printing (3DCP), offers inherent advantages that significantly contribute to the realization of these circular economy principles. The technology's precise, layer-by-layer deposition process inherently reduces material waste compared to conventional construction methods . This efficiency is further enhanced by its design flexibility, which facilitates the integration of recycled materials and the creation of components optimized for disassembly and future reuse.

A primary application of CE principles in 3DPC involves the valorization of construction and demolition waste (CDW) by incorporating recycled aggregates (RA) into concrete mixes . This approach directly addresses the growing challenge of managing construction waste and conserves natural resources by reducing the reliance on virgin materials . For instance, the Recycl3D project explicitly frames its objectives around improving the recovery and recycling of CDW, particularly fine recycled aggregates (fRA), for use in higher-grade 3DPC structures, thereby enhancing material efficiency and creating a clear entry point into the circular economy value chain .

Beyond aggregates, the substitution of cement with recycled materials is another critical aspect. Research has investigated the use of recycled concrete powder as a viable low-carbon alternative to Portland cement in 3DPC mixes, contributing to reduced environmental footprints and lower carbon emissions . Similarly, the development of 3D printing mortars utilizing locally sourced demolition waste as a substitute for sand emphasizes the urgent need for alternatives to address increasing sand demand, aligning with circular economy objectives .

Furthermore, the circular economy principles extend to the recycling of 3DPC itself. A core strategy involves reusing waste 3DPC to produce fine recycled aggregates (fRA), which can then substitute cement in new 3DPC applications, directly supporting waste reduction and resource efficiency . This closing of material loops is exemplified by business models that position 3D concrete printing with recycled fine aggregates (RFA) as a means to achieve a closed-loop system for demolition waste. Such models contrast sharply with the linear "manufacture, use, discard" paradigm, aiming for continuous product utility. An example is the creation of urban furniture from RFA, giving waste a new purpose and decreasing the reliance on virgin sand. These models also integrate mechanisms for product return, maintenance, and reuse, fostering a more comprehensive circularity . Overall, the emphasis on utilizing "end-of-cycle materials from the industry" in 3D-printed concrete underscores its potential for significant reductions in embodied CO2 emissions and material waste, effectively supporting circular economy principles .

3.2 Design for Disassembly (DfD) in 3DPC

Design for Disassembly (DfD) is a critical principle for advancing circular economy (CE) objectives within the realm of 3D-printed concrete (3DPC) by enabling the recovery and recycling of materials at the end of a structure's life. DfD mandates the use of reversible construction strategies, allowing for the easy separation and retrieval of components or materials for subsequent reuse or recycling . This approach directly supports CE principles by mitigating waste and minimizing the demand for virgin resources.

Key strategies and methods proposed for designing 3DPC elements with DfD in mind include the adoption of mechanical and reversible connections, ensuring easy accessibility to these connections, and facilitating the straightforward separation of individual elements . Furthermore, the avoidance of chemical coatings or adhesives is crucial, as these can impede material recovery and purity during recycling processes .

A notable case study illustrates the application of these DfD principles through the design of 3DPC vaults without conventional reinforcement . In this design, production waste is integrated as filler, demonstrating an immediate closed-loop material flow. The assembly and disassembly processes are streamlined through the use of friction-based joints between modules and simple lifting anchors, which allow for efficient deconstruction and material recovery .

The inherent characteristics of 3D printing, such as the ability to produce customized shapes and optimize design for reduced material usage, indirectly support DfD by potentially leading to lighter structures that are easier to handle during deconstruction . Moreover, the modular nature often associated with 3D-printed parts inherently facilitates easier disassembly, aligning with DfD objectives . On-site fabrication capabilities, a benefit of additive manufacturing, could further simplify the design and implementation of repairable or disassemblable elements .

While some research, such as the Recycl3D project, focuses on the recoverability and recyclability of 3D-printed concrete made with recycled aggregates, explicit mention of "Design for Disassembly" principles is not consistently present across all studies . However, the general concept of designing for circularity, as seen in discussions around modularity and durability for furniture products, suggests a broader shift towards considering end-of-life scenarios in design, including the potential for grinding up and reusing materials or repurposing components . Despite some papers not explicitly detailing DfD , the increasing emphasis on modularity and simplified connections in 3DPC underscores a growing recognition of DfD's importance in achieving a truly circular construction industry.

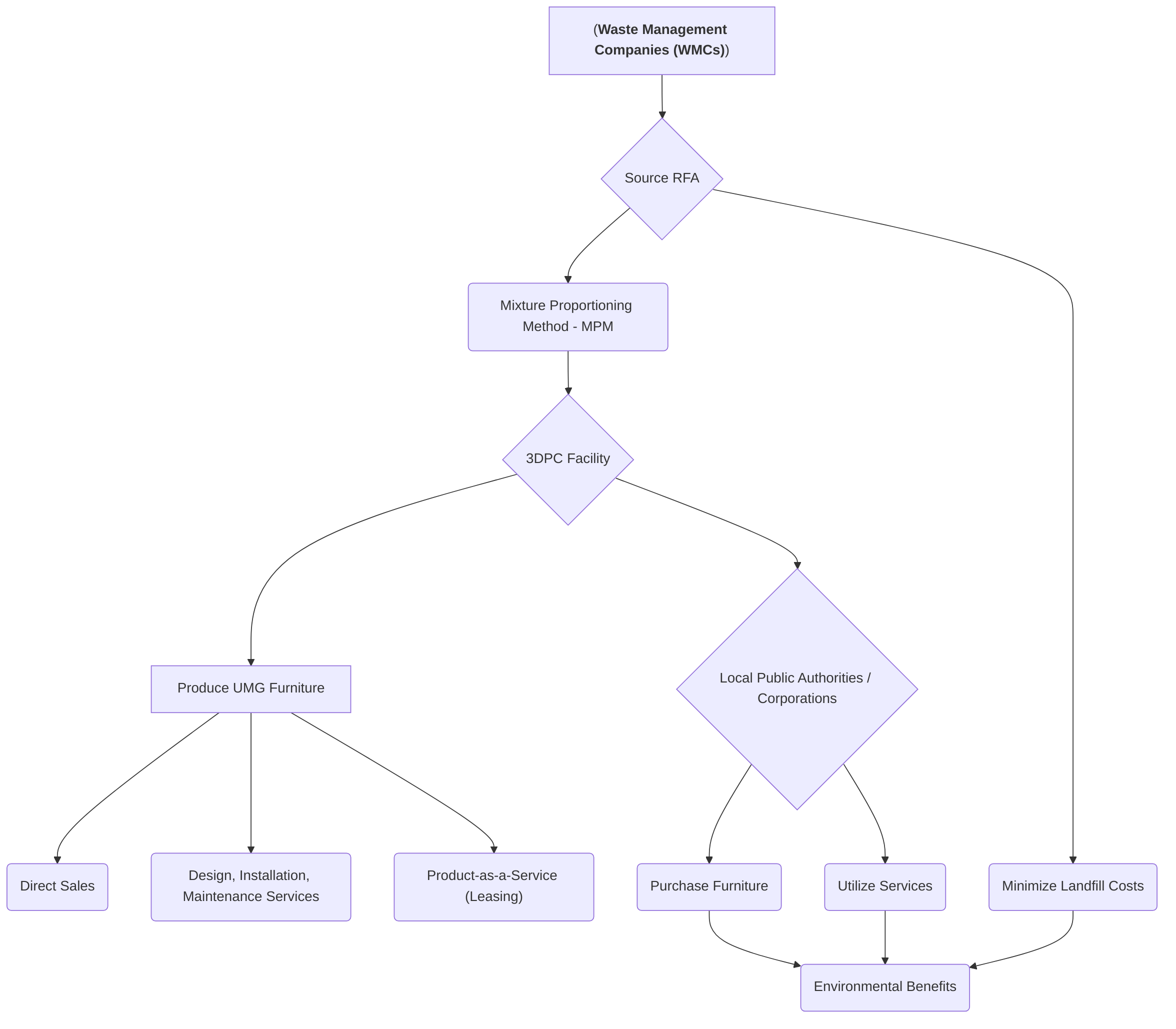

3.3 Business Models for Circular 3DPC

The transition towards a circular economy in the construction sector necessitates the development of innovative business models, particularly for emerging technologies like 3D concrete printing (3DCP) utilizing recycled fine aggregates (RFA). A prominent model in this domain is proposed by a study focusing on a 3DCP facility that integrates RFA into the production of Urban, Memorial, and Garden (UMG) furniture .

This model emphasizes the strategic sourcing of RFA from Waste Management Companies (WMCs) and employs a Mixture Proportioning Method (MPM) to manage the inherent variability of recycled materials, ensuring consistent product quality. The target clientele for such a model primarily includes local public authorities and corporations, reflecting a focus on localized demand and resource utilization .

The viability of this circular business model is underpinned by diverse income streams. These include direct sales of generic UMG products through third-party resellers, as well as the provision of design, installation, and maintenance services . A particularly forward-thinking aspect is the exploration of a "product-as-a-service" model, where products are leased rather than sold, fostering greater resource efficiency and product longevity. Furthermore, the model advocates for localism, suggesting that 3DCP plants should be strategically located near urban centers. This minimizes transportation costs and associated carbon emissions for both feedstock acquisition and product distribution, enhancing the model's overall sustainability and economic attractiveness .

The CIRMAP project provides a practical illustration of such an application-driven business model, focusing on developing mortars from locally sourced demolition waste for 3D printing UMG furniture for local authorities . This project successfully demonstrated the concept by showcasing physical objects in multiple partner countries, thereby validating the potential for specific application-driven market uptake of recycled materials in 3DPC products . The "Project Recycled Aggregates for 3D Printed Concrete Structures" further supports this by aiming to overcome market uptake barriers through the design and optimization of 3D-printed concrete structural prototypes using recycled aggregates, ultimately seeking to make these applications economically viable and scalable for industry adoption .

When comparing and contrasting the viability and scalability of these circular economy business models for 3DPC, several factors emerge. The proposed model offers a comprehensive framework that addresses not only product creation but also supply chain integration, revenue generation, and sustainable operations. Its emphasis on RFA sourcing from WMCs and the use of MPM for quality control directly tackles key challenges related to material variability and availability, which are critical for scalability. The diversification of income streams, including product sales, services, and leasing, also enhances its economic viability compared to models solely reliant on direct product sales. The localism aspect of this model significantly contributes to its environmental and economic sustainability, reducing logistical complexities and costs often associated with widespread material sourcing and distribution.

In contrast, while the CIRMAP project provides a compelling proof-of-concept for localized, application-specific use of recycled materials in 3DPC, its direct discussion on broader business model elements, such as supply chain considerations beyond local sourcing, diverse income streams, or comprehensive stakeholder collaboration, is less explicit than the detailed proposal in . However, both models align in their focus on UMG furniture and targeting local authorities, suggesting a viable niche market for circular 3DPC products. The economic benefits of incorporating RFA are also highlighted by research indicating that increasing RFA addition can significantly reduce mix costs by up to 24%, thereby implying a considerable economic advantage for these circular business models .

Practical implications and challenges in implementing these models include the consistent availability and quality of RFA, which necessitates robust supply chain management and material characterization techniques like MPM . Furthermore, market acceptance and demand for recycled 3DPC products, especially from public authorities and corporations, will be crucial. The "product-as-a-service" model, while promising for sustainability, may face initial hurdles in consumer adoption and requires robust legal and operational frameworks. Moreover, while some studies acknowledge economic benefits from RFA inclusion , comprehensive economic viability assessments, including detailed cost-benefit analyses, are essential for widespread implementation. Other relevant papers, while contributing to the understanding of 3DPC or recycled materials, do not explicitly delve into business models, supply chain considerations, or stakeholder collaboration, thus highlighting the specialized focus of the aforementioned studies .

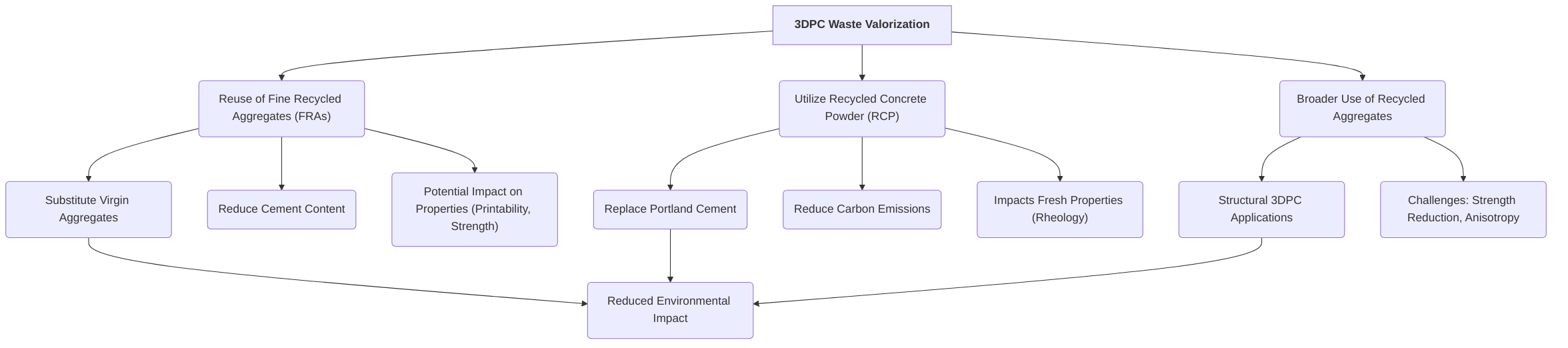

3.4 Strategies for Material Valorization in 3DPC

The valorization of 3D-printed concrete (3DPC) waste is a critical strategy for advancing circular economy principles within the construction sector, particularly in the context of carbon neutrality. This section provides a comparative overview of various material valorization strategies, synthesizing findings from the subsequent subsections to identify common themes, challenges, and successful approaches in transforming 3DPC waste into valuable resources. The overarching goal is to reduce reliance on virgin materials, mitigate CO2 emissions, and enhance the sustainability of 3DPC construction .

Three primary strategies for valorizing 3DPC waste are explored: the reuse of fine recycled aggregates (FRAs) derived from 3DPC waste, the utilization of recycled concrete powder (RCP) in new 3DPC mixes, and the broader application of various recycled aggregates for structural 3DPC elements. Each approach aims to substitute conventional materials—such as virgin aggregates and Portland cement—with recycled alternatives, thereby reducing environmental impact .

The reuse of FRAs from 3DPC waste primarily focuses on replacing virgin aggregates and potentially reducing cement content. Studies, such as that by Qasem et al. (2023), demonstrate that incorporating FRAs can significantly decrease equivalent CO2 emissions (up to 48%) and mix cost (up to 24%) . However, higher replacement rates (e.g., above 20 vol% as cement replacement) can negatively impact critical properties such as printability, green strength, setting time, and mechanical strength . This highlights a common challenge: balancing environmental benefits with the need to maintain mechanical and rheological performance. The preparation of FRAs typically involves crushing and sieving .

Similarly, the utilization of RCP in 3DPC mixes offers a promising pathway to reduce the carbon footprint by replacing a portion of Portland cement. RCP, often derived from lab-cast specimens (RCP-L) or ready-mix plant waste (RCP-C), has been shown to reduce carbon emissions by up to 62% . The physical and chemical properties of RCP significantly influence the fresh properties of 3DPC, with variations in yield stress and viscosity depending on the source, which in turn affect extrudability and buildability . While RCP offers significant environmental advantages and can influence fresh properties favorably, detailed long-term performance data for hardened properties remain an area requiring further investigation, as explicitly noted in the discussion of the provided digest for .

Beyond fine recycled aggregates and powders, there is a growing focus on the broader use of various types of recycled aggregates, including those from construction and demolition waste (CDW), in structural 3DPC applications. Projects like Recycl3D aim to integrate fRA from CDW into new concrete elements through 3D printing, intending to enhance market uptake and design structural prototypes . This contrasts with applications limited to non-structural uses or cement substitution . For example, the incorporation of 3DPC production waste as crushed concrete filler into slab designs represents a step towards a broader application of recycled materials . While promising, the incorporation of broader recycled aggregate types, such as those used by Hyperion Robotics to achieve significant material efficiency, also presents challenges regarding strength reduction and increased anisotropy, necessitating meticulous material characterization and mix design optimization .

Common themes across these valorization strategies include the significant environmental benefits derived from reducing virgin material consumption and carbon emissions. However, a pervasive challenge is the potential compromise in mechanical and rheological properties of 3DPC when incorporating recycled materials, especially at higher replacement rates. This necessitates careful mix design, material characterization, and process optimization to ensure adequate performance for structural applications. A critical research gap identified across all strategies is the lack of comprehensive long-term durability studies. While initial strength and fresh properties are often assessed, detailed data on resistance to freeze-thaw cycles, alkali-aggregate reaction, carbonation, creep, and shrinkage are largely absent, hindering the widespread adoption and reliability of these sustainable 3DPC solutions . Future research should prioritize developing standardized processing methods for various recycled materials, conducting extensive long-term performance evaluations, and optimizing mix designs to balance sustainability benefits with required structural integrity and longevity.

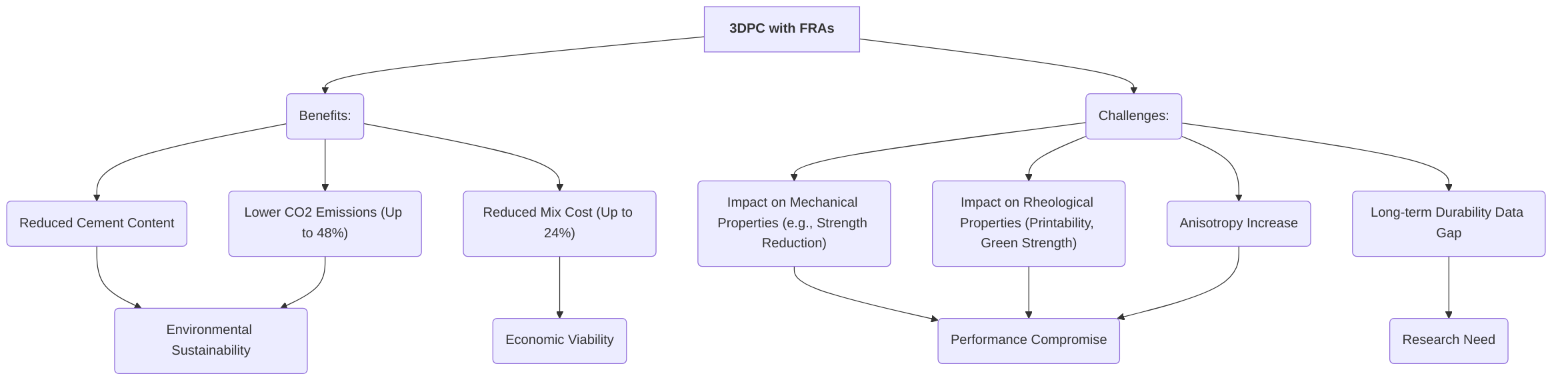

3.4.1 Reusing 3DPC Fine Recycled Aggregates (FRAs)

The reuse of fine recycled aggregates (FRAs) derived from 3D-printed concrete (3DPC) waste presents a promising pathway toward reducing the environmental footprint of concrete construction by minimizing reliance on virgin aggregates and potentially decreasing cement content. The process of obtaining FRAs from discarded 3DPC typically involves crushing and sieving the waste material to achieve the desired particle size distribution . This approach aligns with circular economy principles by valorizing industrial by-products and demolition waste, thereby reducing the demand for natural resources .

The effectiveness of FRAs in new 3DPC formulations has been investigated, with studies exploring their impact on reducing the need for virgin aggregates and decreasing cement content. Research by Qasem et al. (2023) demonstrated that incorporating FRAs from waste 3DPC can significantly reduce cement content, leading to a substantial decrease in equivalent CO2 emissions (up to 48%) and mix cost (up to 24%) . Similarly, other studies have explored using recycled aggregates (RA) from demolition waste to replace natural aggregates in 3DPC, with replacement rates ranging from 30% to 50% . A circular business model for 3D concrete printing with recycled fine aggregates has also been proposed, suggesting that FRAs from end-of-life 3D-printed products could be recycled back into new mortar formulations for applications like UMG furniture .

Despite the environmental benefits, the incorporation of FRAs significantly influences the mechanical and rheological properties of new 3DPC mixes. Qasem et al. (2023) reincorporated FRAs into new 3DPC mixes at replacement rates of cement by 10, 20, 30, 40, and 50 vol% . While lower replacement rates showed promise, higher replacement rates (above 20 vol%) negatively impacted critical properties such as printability window, green strength, setting time, and mechanical properties . Specifically, the study reported that increasing fRA content from 0% to 50% (by volume of cement) resulted in a decrease in compressive strength from approximately 50 MPa (0% fRA) to less than 20 MPa (50% fRA) at 28 days. The flexural strength also decreased from around 8 MPa (0% fRA) to less than 4 MPa (50% fRA) with increasing fRA content . These findings indicate a compromise between sustainability benefits and performance characteristics. In another study, replacing 30% and 50% of natural aggregates with RA was found to reduce the strength of the concrete and increase its anisotropy .

A comparative analysis of performance metrics for 3DPC mixes incorporating FRAs reveals varying outcomes based on replacement rates and aggregate processing methods. For instance, while Qasem et al. (2023) observed significant reductions in mechanical properties at higher fRA replacement rates, the initial properties of the fRA, such as particle size distribution, were characterized to understand their influence . In contrast, approaches that utilize broader demolition waste as a substitute for sand emphasize managing the variability of recycled fine aggregate composition through methods like a Mixture Proportioning Method (MPM) to achieve a 50% RFA by total volume in mortars . This highlights the importance of specific processing methods and mix designs in mitigating the negative impacts on performance.

Despite the promising advancements, a critical gap in the existing research pertains to the long-term durability and potential performance degradation of 3DPC when incorporating FRAs derived from 3D-printed waste. While some projects aim to predict the mechanical, durability, and service-life of 3D-printed concrete elements made with recycled aggregates, comprehensive experimental data on the long-term performance, including resistance to freeze-thaw cycles, alkali-aggregate reaction, and carbonation, are largely missing . Future research should focus on developing standardized processing methods for FRAs from 3DPC waste and conducting extensive long-term durability studies to ensure the reliability and safety of structures built with these recycled materials. This will be crucial for establishing robust benchmarks and promoting the widespread adoption of circular economy principles in 3DPC construction.

3.4.2 Utilizing Recycled Concrete Powder (RCP) in 3DPC Mixes

Recycled Concrete Powder (RCP) serves as a promising low-carbon alternative in 3D-printed concrete (3DPC) mixes, primarily by replacing a portion of conventional Portland cement, thereby significantly reducing carbon emissions associated with cement production . The incorporation of RCP aligns with circular economy principles by valorizing construction and demolition waste.

A key study investigated the replacement of up to 50% of Portland cement with two types of RCP: RCP-L, derived from lab-cast specimens, and RCP-C, sourced from ready-mix plant waste . The preparation of these RCPs involved characterizing their physical and chemical properties, including particle size, density, Blaine fineness, surface area, and chemical composition. These intrinsic properties of RCPs are critical as they dictate their reactivity and interaction within the cementitious matrix.

The effects of RCP on the fresh and hardened properties of 3DPC were comprehensively evaluated. In terms of fresh properties, the study assessed rheological characteristics such as static yield stress and plastic viscosity, and hydration behavior using isothermal calorimetry . Printability was evaluated through extrudability and buildability tests. While specific quantitative data on hardened properties like compressive strength and durability impacts were not detailed in the provided digest for direct comparison, the study did indicate variations in rheological performance based on the RCP source. Specifically, RCP-L generally exhibited superior rheological performance with higher yield stress, which is beneficial for maintaining shape stability in 3DPC. Conversely, RCP-C, characterized by lower viscosity, facilitated better extrusion during the printing process . This highlights that the source and processing methods of RCP significantly influence the fresh properties crucial for 3D printing. The study also reported a substantial reduction in carbon emissions, achieving up to 62% by replacing cement with RCP .

Comparing RCP-blended 3DPC mixes with conventional 3DPC mixes based solely on the provided digest, it is evident that RCP offers a significant environmental advantage through carbon emission reduction. However, a direct quantitative comparison of strength and durability metrics (e.g., compressive strength, flexural strength, freeze-thaw resistance, or shrinkage) between RCP-blended and conventional 3DPC mixes is not explicitly detailed in the current digest for . The digest focuses more on the fresh properties and environmental benefits rather than the long-term mechanical performance. Other papers like do not discuss the utilization of RCP in 3DPC mixes. Furthermore, the provided digests do not contain direct information on RCP from . This absence underscores a crucial gap in the current set of digested literature, necessitating the consultation of external research or highlighting this as a critical area for future investigation.

To provide a more comprehensive understanding, a comparative analysis of performance metrics for 3DPC mixes incorporating RCP from different studies would typically involve:

| Performance Metric | RCP-L Blended Mix (Example) | RCP-C Blended Mix (Example) | Conventional 3DPC Mix (Example) |

|---|---|---|---|

| Processing Method of RCP | Lab-cast specimens | Ready-mix plant waste | N/A |

| Static Yield Stress | Higher (beneficial for buildability) | Lower | Baseline |

| Plastic Viscosity | Higher | Lower (aids extrusion) | Baseline |

| Extrudability | Good (impacted by viscosity) | Better (due to lower viscosity) | Baseline |

| Buildability | Better (due to higher yield stress) | Good | Baseline |

| Carbon Emission Reduction | Up to 62% | Up to 62% | 0% (relative to RCP mixes) |

| Compressive Strength (e.g., 28 days) | Not explicitly detailed | Not explicitly detailed | Baseline |

| Durability Indicators (e.g., shrinkage, freeze-thaw) | Not explicitly detailed | Not explicitly detailed | Baseline |

The critical missing research, as highlighted by the current digests, pertains to the long-term durability and potential performance degradation of 3DPC when incorporating RCP. While initial studies indicate promising fresh properties and environmental benefits, detailed experimental data on the long-term mechanical strength, resistance to environmental degradation (e.g., carbonation, chloride ingress, freeze-thaw cycles), and microstructural stability of RCP-blended 3DPC are largely absent from the provided information. Future research should focus on these aspects to ensure the widespread and reliable application of RCP in structural 3DPC elements.

3.4.3 Broader Use of Recycled Aggregates for 3D-Printed Concrete Structures

While previous discussions often center on the use of fine recycled aggregates (fRA) or cementitious powders from 3D-printed concrete (3DPC) waste, a broader exploration into the applicability of various types of recycled aggregates in 3DPC for structural applications is crucial. The Recycl3D project, for instance, specifically investigates the utilization of fRA derived from construction and demolition waste (CDW) in novel 3D printing technologies to produce new concrete elements . This initiative aims to enhance the market uptake of CDW recycling by integrating it into higher-grade applications and to design, optimize, and test the performance of 3D-printed concrete structural prototypes containing these recycled aggregates .

This broader approach contrasts with studies primarily focused on fRA as a cement substitute or for non-structural applications. For example, some research specifically examines fRA from 3DPC waste for cement replacement , while others, such as the CIRMAP project, concentrate on using demolition waste as a substitute for sand in 3D printing mortars for customized shapes . While these studies contribute valuable insights into fine aggregate utilization, they do not extensively delve into the broader spectrum of recycled aggregate types or their structural performance beyond fine aggregates and powders. For instance, the use of production waste as crushed concrete filler within slab designs represents a step towards broader application, but it remains a specific form of recycled material . Similarly, research on recycled fine aggregates (RFA) for furniture, while acknowledging the potential for RFA to be crushed into larger aggregates for construction, does not directly address large-scale structural applications requiring stringent standards .

Promisingly, ongoing projects demonstrate the viability of using broader types of recycled aggregates in 3DPC. Hyperion Robotics, for example, successfully incorporates a combination of end-of-cycle materials, including demolition waste, into 3D-printed concrete, as evidenced by a 3D-printed pad foundation that used only 25% of the material of a traditional foundation while achieving equivalent strength . This indicates substantial improvements in material efficiency and reduced reliance on virgin aggregates .

However, the incorporation of recycled aggregates, even beyond fine types, presents challenges. A study on replacing 30% and 50% of natural aggregates with recycled aggregates (RA) in 3DPC observed a reduction in strength and an increase in anisotropy . This highlights the need for meticulous material characterization and mix design optimization when utilizing diverse types of recycled aggregates to mitigate negative impacts on mechanical properties.

A comparative analysis of performance metrics for 3DPC mixes incorporating various types of recycled aggregates reveals distinct characteristics. While fine recycled aggregates from 3DPC waste can act as cement substitutes, their primary impact is on early-age strength and rheology. The broader incorporation of demolition waste, which can include both fine and coarse fractions, directly influences the bulk properties of the concrete, such as compressive strength and potentially durability. For instance, the Hyperion Robotics project's success with demolition waste suggests optimized mix designs that overcome potential strength reductions often associated with higher RA content.

The primary missing research concerning the broader application of recycled aggregates in 3DPC lies in understanding the long-term durability and potential performance degradation. While initial strength and workability are often assessed, comprehensive studies on creep, shrinkage, freeze-thaw resistance, and chemical attack resistance of 3DPC incorporating diverse recycled aggregate types are scarce. Such research is critical to ensure the structural integrity and longevity of these sustainable constructions, especially in various environmental conditions. Furthermore, detailed investigations into the optimal processing methods for different types of recycled aggregates (e.g., crushing techniques, washing, particle size distribution control) and their specific impact on the rheological properties crucial for 3D printing, such as extrudability, buildability, and open time, are also areas requiring further research.

4. Pathways to Carbon Neutrality for 3D-Printed Concrete

Achieving carbon neutrality in the context of 3D-printed concrete (3DPC) requires a holistic approach that integrates waste reduction, the strategic utilization of low-carbon concrete, and the efficient recycling of 3D-printed materials . This section outlines the synergistic pathways through which these elements collectively contribute to decarbonizing the construction sector, particularly within additive manufacturing processes.

The initial pathway towards carbon neutrality involves minimizing material waste inherent in construction processes. 3D printing inherently offers significant waste reduction capabilities compared to conventional construction methods . This efficiency is further enhanced by design optimization, such as the creation of hollow structures, which can substantially decrease overall material consumption and, by extension, the embodied carbon associated with production .

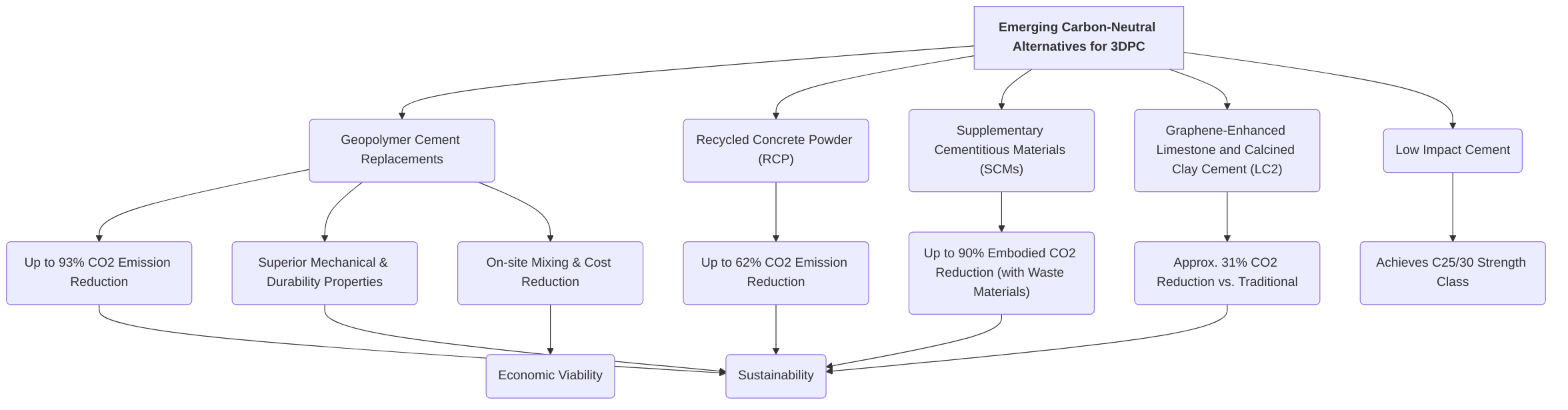

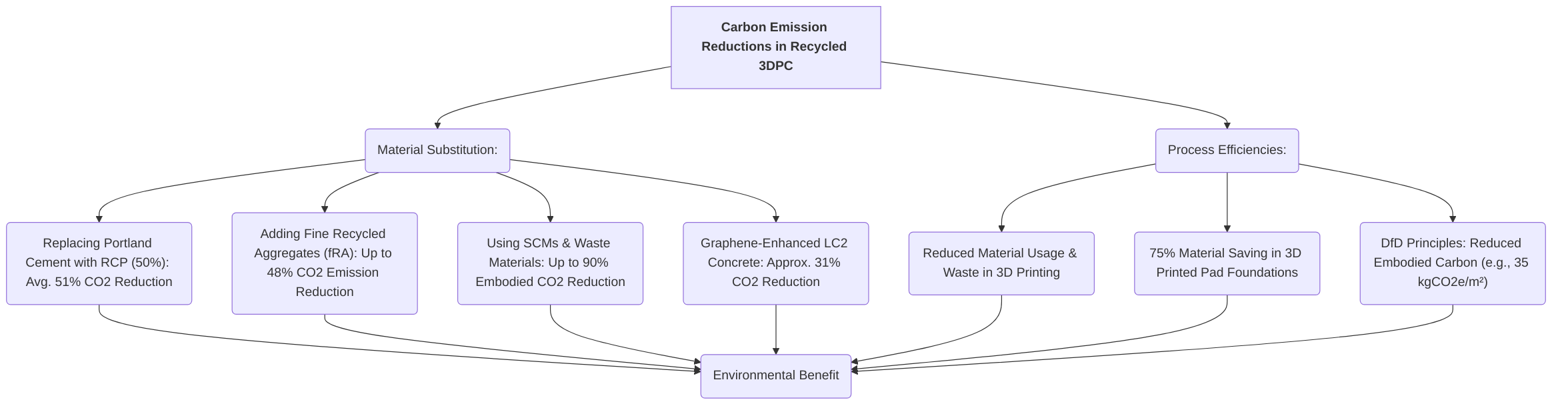

The second crucial pathway is the development and adoption of low-carbon concrete materials. This involves substituting traditional Portland cement, a significant contributor to CO2 emissions, with alternatives such as geopolymer cements, recycled concrete powder (RCP), and various supplementary cementitious materials (SCMs). For instance, carbon-neutral geopolymer materials can achieve up to a 93% reduction in CO2 emissions, while RCP can replace 50% of cement, leading to a 62% reduction in CO2 . Innovations like limestone and calcined clay cement (LC2) enhanced with graphene also contribute to significant emission reductions, approximately 31% compared to traditional printable concrete mixtures . These advancements underscore the potential for low-carbon concrete inks and alternative binders to drastically lower the carbon footprint of 3DPC .

The third integral pathway centers on the recycling of 3D-printed concrete materials. This involves the reuse of 3DPC waste as fine recycled aggregates (fRA) . By incorporating fRA, the need for virgin sand extraction and processing is reduced, thereby decreasing the carbon footprint associated with sand mining, desalination, processing, and transportation . Furthermore, reusing 3DPC waste as fRA can significantly reduce the cement content in new concrete mixes, leading to a substantial decrease in associated CO2 emissions . This circular economy approach, which includes the integration of Design for Disassembly (DfD) principles into 3DCP, promotes more sustainable construction practices and directly supports carbon neutrality by reducing embodied carbon .

The synergy among these three pathways is critical for achieving carbon neutrality. Waste reduction in 3D printing minimizes the volume of materials requiring disposal or recycling, thereby reducing the associated energy and emissions. The use of low-carbon materials directly lowers the embodied carbon of concrete. Simultaneously, the recycling of 3D-printed concrete closes the loop, transforming waste into valuable resources and further reducing the reliance on virgin materials and their associated carbon-intensive production processes. Localized production facilitated by 3DPC further minimizes transportation emissions, enhancing the overall carbon neutrality goal . The combined impact of these strategies—efficient material use, adoption of low-carbon alternatives, and robust recycling loops—creates a comprehensive framework for significantly reducing the environmental footprint of 3DPC and propelling the construction industry towards carbon neutrality. While challenges such as ensuring material consistency, scalability, and regulatory acceptance persist, the integration of these approaches offers a promising trajectory for sustainable construction .

4.1 Emerging Carbon-Neutral Alternatives for 3DPC

The pursuit of carbon neutrality in 3D-printed concrete (3DPC) necessitates the development of innovative materials that can serve as direct, low-carbon, or carbon-neutral alternatives to traditional Portland cement. While some literature broadly acknowledges the potential for sustainable materials like fly ash or biomass waste , and the concept of "low-carbon concrete inks" is recognized as a key strategy , specific novel materials with detailed emission reduction potentials are increasingly being explored.

A significant stride in this direction is the development of geopolymer cement replacements, which offer substantial CO2 emission reductions compared to conventional cement. For instance, Hive3D Builders has engineered a carbon-neutral geopolymer material achieving a remarkable 93% reduction in CO2 emissions . This material not only requires less energy for production but also exhibits superior mechanical properties, including enhanced strength, durability, and fire resistance. The technical feasibility of such alternatives is further bolstered by innovative systems for on-site mixing with locally sourced aggregates, which can reduce material costs significantly, thereby promoting the widespread adoption of additive manufacturing .

Beyond geopolymers, other low-carbon alternatives are emerging. Recycled concrete powder (RCP) has been investigated as a viable substitute for Portland cement in 3DPC mixes. Studies have demonstrated that replacing 50% of cement with RCP can lead to CO2 emission reductions of up to 62% . This indicates RCP's potential as a valuable component in circular economy approaches for concrete. Similarly, the integration of supplementary cementitious materials (SCMs) and waste products, such as blast furnace slag and fly ash, into "low-carbon concrete" formulations has shown promise in reducing embodied CO2 emissions by up to 90% . Another advancement involves the use of limestone and calcined clay cement (LC2) enhanced with graphene as a novel low-carbon binder for 3D printing, which also contributes to significant reductions in carbon emissions . Even "low impact cement" has been noted in 3DCP mix designs, achieving a strength class of C25/30 .

While these emerging alternatives offer substantial CO2 reduction potentials, their widespread adoption faces several challenges. Technical feasibility often hinges on ensuring that these materials meet the specific rheological and mechanical requirements for 3D printing, such as pumpability, extrudability, and buildability, while maintaining long-term durability and performance comparable to traditional cement-based mixes. Furthermore, the scalability of production, consistency of material properties, and regulatory frameworks for new construction materials are crucial factors influencing their future outlook. Despite these hurdles, the ongoing research and development into geopolymer cements, recycled concrete powder, and various SCMs present promising pathways toward achieving carbon neutrality in 3DPC. Continued efforts are needed to optimize their performance, reduce costs, and standardize their application to facilitate their integration into mainstream construction practices.

5. Life Cycle Assessment and Economic Considerations

This section provides a comprehensive overview of the environmental and economic implications of recycling 3D-printed concrete (3DPC) materials, a critical aspect for advancing carbon neutrality in the construction sector. It synthesizes findings from various life cycle assessment (LCA) studies to delineate the environmental benefits of recycled 3DPC and identifies key stages within the material lifecycle where significant environmental impacts or savings are realized. Furthermore, the section delves into the economic feasibility of 3DPC recycling, evaluating processing costs against potential material savings and discussing current limitations alongside future prospects for industrial-scale implementation. A critical comparison of economic data, drawing insights from business models, illuminates cost estimations, scalability challenges, and the underlying assumptions in economic analyses, particularly those presented in . This integrated analysis aims to provide a holistic understanding of the sustainability credentials and market potential of recycled 3DPC, highlighting both its promise and the remaining hurdles for widespread adoption.

5.1 Environmental Life Cycle Assessment of Recycled 3DPC

The environmental life cycle assessment (LCA) of 3D-printed concrete (3DPC) incorporating recycled materials is a nascent but critical area of research for achieving carbon neutrality in construction. Current findings, while limited, indicate substantial environmental benefits from the production and utilization of recycled aggregates (RA). For instance, an LCA by demonstrates that RA production has a significantly lower environmental impact compared to natural sand production. This study also emphasizes the critical role of transportation distance, suggesting it should not exceed 25 km to maintain environmental benefits, a finding supported by which informed optimal transportation distances for recycled fine aggregates (RFA).

Despite these initial insights, a comprehensive understanding is hampered by a notable absence of cradle-to-grave comparative LCAs specifically for recycled 3DPC . This limitation restricts the ability to fully quantify the environmental impacts and benefits across the entire lifecycle, from raw material extraction to end-of-life disposal or recycling.

Several studies highlight significant carbon emission reductions stemming from material substitution and process efficiencies inherent in 3DPC technology. Regarding material substitution, replacing traditional cement and virgin aggregates with recycled alternatives is a primary driver of carbon savings. For example, replacing 50% of Portland cement with recycled concrete powders (RCPs) can lead to an average reduction of 51% in carbon emissions . Similarly, increasing the addition of fine recycled aggregates (fRA) can result in a substantial decrease in equivalent CO2 emissions, up to 48% in some cases, as fRA and fly ash contribute very little to global warming potential . Moreover, utilizing recycled materials like blast furnace slag, fly ash, and demolition waste in low-carbon concrete mixes can achieve a remarkable 90% reduction in embodied CO2 emissions . The integration of novel materials, such as graphene-enhanced LC2 concrete, has also been shown to reduce greenhouse gas emissions by approximately 31% compared to traditional printable concrete mixtures .

Beyond material composition, process efficiencies intrinsic to 3DPC technology contribute significantly to carbon footprint reduction. 3D printing inherently leads to reduced material usage and waste production compared to conventional construction methods . For instance, a 3D-printed pad foundation can save 75% of material compared to traditional foundations, implying substantial environmental benefits in terms of resource consumption and associated carbon footprint . Furthermore, designing 3DPC elements with Design for Disassembly (DfD) principles can lead to significant reductions in embodied carbon over the lifecycle, as evidenced by a 3DCP hybrid slab with an embodied carbon of 35 kgCO2e/m², comparable to a CLT slab option (34.5 kgCO2e/m²) .

The methodologies employed for carbon footprint assessment vary, leading to some discrepancies and areas for further investigation. While some studies focus on specific material substitutions and their impact on Global Warming Potential (GWP) within a cradle-to-gate scope , others extend LCA calculations to include broader aspects of use and material recovery (B and C phases) . A critical stage identified for significant environmental impact or savings is the production of raw materials, particularly cement, and the transportation of both virgin and recycled aggregates. The ecological cost of extracting new sand is also a critical consideration .

Despite these valuable contributions, there are significant data gaps concerning specific environmental indicators and lifecycle stages. Comprehensive data on embodied energy, resource depletion, and various other environmental indicators beyond GWP are frequently absent or highly limited in the reviewed literature . Furthermore, detailed quantitative data on carbon emission reductions specifically attributable to the incorporation of recycled materials into 3DPC are not consistently detailed across studies .

The methodologies for carbon footprint assessment, while providing valuable insights, often involve assumptions and limitations. The scope of LCA studies, for instance, can vary from assessing raw material production to considering the entire use and recovery phases . These variations can lead to different reported carbon footprints, making direct comparisons challenging. Future research should strive for standardized LCA methodologies, clearer reporting of system boundaries, and a more comprehensive assessment of environmental indicators to provide a holistic understanding of the environmental performance of recycled 3DPC.

5.2 Economic Viability and Scalability

The economic viability of recycling 3D-printed concrete (3DPC) materials is a critical factor influencing their widespread adoption in a circular economy. Several studies highlight potential cost savings associated with the use of recycled materials and the inherent efficiencies of 3D printing technology. For instance, the incorporation of end-of-cycle materials is noted to contribute to "significant cost savings" . Similarly, the application of 3D printing itself is suggested to decrease project costs and lead-times, particularly through onsite fabrication which reduces the need for molds, transport, and storage, thereby implying economic benefits alongside environmental ones . The "fast and economical manner" of customized geometry production through Additive Manufacturing (AM) further underscores these potential advantages .

Specifically, the use of fine recycled aggregates (fRA) has been demonstrated to reduce mix costs. One study indicates that increasing fRA addition can lead to a substantial reduction in mix cost, potentially up to 24%, suggesting the economic viability of this strategy . Furthermore, by automatically mixing cement replacement with locally sourced aggregates on-site, Hive3D Builders has reportedly reduced the price of their printing mortar to a third of commercially available options, presenting a compelling economic incentive for construction companies to adopt 3D concrete printing . Diverting recycled fine aggregates (RFA) to 3D printing also offers cost reductions for Waste Management Companies (WMCs) by minimizing transportation and landfill expenses .

Despite these promising indications of cost savings, a comprehensive analysis of the full economic lifecycle, including the costs associated with the collection and processing of waste 3DPC into fRA, is often not detailed in the literature . While some papers mention the aim for fast and low-cost assembly and disassembly through Design for Disassembly (DfD) strategies , specific economic data related to the recycling process itself, such as processing costs versus material savings, are largely absent in several reviewed works .

The scalability of 3DPC recycling practices to an industrial level presents both opportunities and challenges. The Recycl3D project, by focusing on designing and optimizing 3D-printed concrete structural prototypes with recycled aggregates, explicitly aims to address barriers to future market uptake and establish a clear entry point for fRA into the circular economy value chain, thereby implying a focus on demonstrating economic viability and scalability for structural applications . However, the scalability of these recycling technologies often remains undiscussed beyond laboratory testing .

A critical comparison of economic data reveals that while individual components of the cost structure are sometimes mentioned, a holistic economic model with explicit assumptions is rare. The "Circular Business Model for 3D Concrete Printing with Recycled Fine Aggregates" provides a more detailed, albeit illustrative, cost structure. It identifies key cost components such as equipment (estimated €26,000-€70,000 for printer and pump), raw materials (RFA at €10-15/tonne versus cement at €347/tonne), and operational costs including rent, electricity, and wages . This paper further discusses how profit can be generated by adding value through bespoke design, consultancy, installation, and maintenance services, effectively selling a "project," or through higher volume sales of generic products via third-party resellers at lower profit margins . The scalability in this model is explicitly linked to feedstock availability and market capacity, highlighting external factors that can influence industrial adoption .

In conclusion, while the economic potential of recycling 3DPC materials is widely acknowledged, particularly through material savings and the inherent efficiencies of 3D printing, detailed economic analyses comparing processing costs to material savings, and comprehensive discussions on the scalability of these practices to an industrial level, remain nascent. Future research needs to establish robust economic models that account for the entire lifecycle costs, including collection, processing, and re-integration, to provide a clearer picture of the overall economic feasibility and to identify pathways for industrial-scale implementation.

6. Challenges, Gaps, and Future Outlook

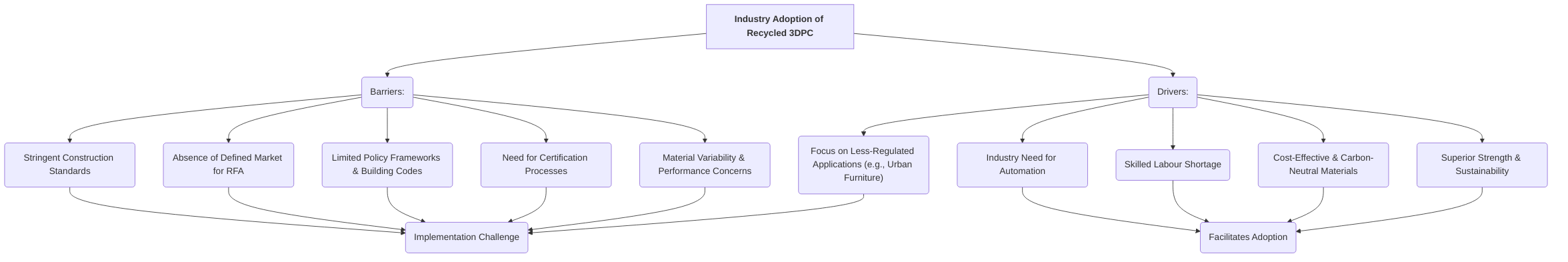

The transition towards a circular economy for 3D-printed concrete (3DPC) materials, crucial for achieving carbon neutrality, is currently confronted by an array of technical, regulatory, and industrial challenges. This section integrates insights from various studies to provide a comprehensive overview of these hurdles, compare different perspectives, and propose interdisciplinary solutions and future research directions to overcome existing limitations .

The primary technical hurdle in achieving consistent quality and performance of recycled 3DPC lies in material variability, particularly concerning recycled fine aggregates (RFA). The diverse origins of construction and demolition waste (CDW) lead to inconsistencies in aggregate composition, particle size distribution, and impurity content, fundamentally hindering standardized production processes . This variability adversely affects key properties such as printability, green strength, setting time, and mechanical properties, especially at higher replacement rates of RFA . For instance, recycled concrete powder (RCP) mixes exhibit greater variability in filament width and occasional edge crumpling, necessitating meticulous calibration . Furthermore, the number of lifecycles RFA can undergo remains largely unquantified, posing a significant knowledge gap . Current pre-treatment and quality control methods are limited, often requiring continuous material characterization and mix proportioning model (MPM) adjustments for each batch, which is not scalable for standardized production .

Beyond technical aspects, stringent construction standards and the absence of a defined market for RFA pose significant regulatory and industry adoption barriers . While initiatives like CIRMAP have targeted less-regulated applications such as urban furniture to circumvent strict building codes , and projects like Recycl3D aim to develop structural prototypes with recycled aggregates , a comprehensive policy framework and certification processes for recycled 3DPC are largely missing from the current discourse. Despite these regulatory hurdles, the construction industry's growing need for automation and the emergence of high-performance, sustainable recycled materials present a compelling case for wider adoption .

To address these multifaceted challenges, an interdisciplinary approach is paramount. Material science can contribute through advanced characterization techniques for waste feedstock and the development of novel binder systems that can compensate for the variability of recycled aggregates, potentially allowing for higher replacement rates . Chemical engineering can offer surface modification techniques to enhance the bonding characteristics of aggregates and mitigate impurity impacts. Data science, particularly artificial intelligence (AI) and machine learning (ML), holds immense potential for predictive modeling for mix design optimization and real-time quality control. Such models could dynamically adjust mix proportions and print settings based on varying recycled material inputs, ensuring consistent performance despite feedstock variability and optimizing both carbon reduction and circularity simultaneously .

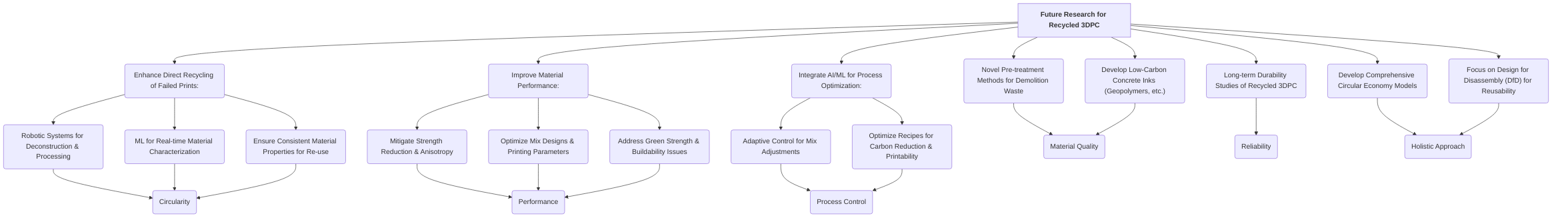

Future research should focus on developing advanced robotic systems and ML algorithms for automated deconstruction and real-time material characterization of 3DPC waste, streamlining the recycling workflow and ensuring consistent properties for re-use . Integration of computational modeling with empirical approaches is crucial to develop and validate mix designs and printing parameters that mitigate strength reduction and anisotropy in recycled 3DPC, striking an optimal balance between flow characteristics and structural buildability . Furthermore, research into novel pre-treatment methods for demolition waste and the development of low-carbon concrete inks, including geopolymer cement replacements and graphene-enhanced materials, are essential for reducing environmental impact and improving material properties for specialized applications . Finally, a holistic understanding of the long-term durability and end-of-life performance of 3DCP elements, alongside the integration of life cycle assessment (LCA) and circularity assessment tools, is critical for informed design for disassembly and re-use, advancing the circular economy goals for 3DPC .

6.1 Current Limitations and Research Gaps

The pursuit of a circular economy for 3D-printed concrete (3DPC) is impeded by several technical hurdles, primarily concerning the consistent quality and performance of recycled materials. A significant challenge lies in the effective recycling of demolition waste aggregate back into concrete, primarily due to inherent impurities and the stringent requirements of established construction standards, necessitating advanced processing or a paradigm shift in material design to facilitate their integration . Specifically, fine recycled aggregates (fRA) derived from construction and demolition waste (CDW) are substantially underutilized, lacking a clear pathway into the circular economy. This underutilization stems from the limited market uptake of CDW recycling products, which can be addressed by developing higher-grade applications and ensuring consistent prediction of mechanical, durability, and service-life properties for 3D-printed elements incorporating recycled aggregates .

Critical research gaps persist, particularly regarding the long-term durability of recycled 3DPC and the standardization of recycled materials. Studies have shown that the use of recycled aggregates (RA) can lead to a reduction in strength and increased anisotropy in 3DPC . Furthermore, the variability of recycled fine aggregates (RFA) presents a significant technical limitation, demanding continuous material characterization and adjustments to mix proportioning models (MPM) for each batch. This variability fundamentally hinders standardized production processes . This issue is further compounded by the observed adverse effects of fRA on the printability window, green strength, setting time, and mechanical properties of 3DPC, especially at replacement rates exceeding 20 vol% of cement . While recycled concrete powder (RCP) shows promise in reducing CO2 emissions, printability tests reveal greater variability in filament width and occasional crumpling at edges, underscoring the need for meticulous calibration of mix properties and print settings when incorporating high RCP content . The number of lifecycles RFA can undergo through repeated recycling also remains largely unquantified .

The underlying causes of material variability in recycled 3DPC can be categorized by feedstock source, processing method, and inherent properties of 3D-printed waste. Feedstock variability stems from the diverse origins of CDW, leading to inconsistencies in aggregate composition, particle size distribution, and impurity content . Processing methods also contribute to variability, as different crushing, sorting, and cleaning techniques can result in varying quality and characteristics of recycled aggregates. The inherent properties of 3D-printed waste itself, such as its unique layered structure and curing conditions, may influence its recyclability and the characteristics of the resulting recycled materials.

Current pre-treatment and quality control methods exhibit limitations in effectively mitigating these variabilities. The necessity for continuous material characterization and MPM adjustments for each batch of RFA highlights the inadequacy of current batch-based quality control approaches for achieving consistent quality . Moreover, the lack of understanding regarding the durability and end-of-life conditions of 3DCP elements due to their novelty further complicates quality assurance . The current focus on material-level circularity in assessment tools, coupled with a deficiency in element-level Design for Disassembly (DfD) evaluations, impedes comprehensive quality control and re-use potential at the structural level .