0. Engineering Bottlenecks and Breakthroughs in the Scalable Manufacturing of Solid-State Batteries

1. Introduction to Solid-State Batteries (SSBs) and Their Potential

Solid-state batteries (SSBs), including all-solid-state batteries (ASSBs), represent a fundamental departure from conventional lithium-ion batteries (LIBs) by replacing flammable liquid or gel electrolytes with non-flammable solid-state electrolytes (SSEs) . This paradigm shift is driven by the inherent limitations of LIBs, which are approaching their performance ceilings in terms of energy density and present significant safety concerns related to thermal runaway and fire risks due to their flammable liquid components . SSBs address these critical issues by offering enhanced safety, higher energy density, and superior longevity.

The common advantages of SSBs consistently highlighted in the literature include substantial improvements across three key performance indicators: energy density, safety, and longevity. In terms of energy density, SSBs are projected to achieve capacities exceeding 500 Wh/kg, significantly surpassing the 350 Wh/kg typically observed in conventional LIBs . This enhanced energy storage capacity is primarily attributed to the ability of solid electrolytes to accommodate high-energy anode materials, such as lithium metal or silicon, enabling thinner electrode layers and higher volumetric and gravimetric energy densities . The safety benefits of SSBs are paramount, stemming from the non-flammable nature of SSEs, which virtually eliminates the risk of leakage, overheating, thermal runaway, and dangerous explosions associated with liquid electrolytes . Furthermore, the mechanical strength of solid electrolytes can inhibit lithium dendrite growth, a common cause of short-circuiting in LIBs . Regarding longevity, SSBs demonstrate improved cycle life due to minimized parasitic side reactions and more stable electrochemical reactions facilitated by the solid electrolyte, leading to reduced degradation of active materials and extended lifespan . Additionally, SSBs offer a wider operating temperature range (e.g., -30°C to +100°C) and the potential for faster charging/discharging rates due to efficient ion transport and reduced internal resistance .

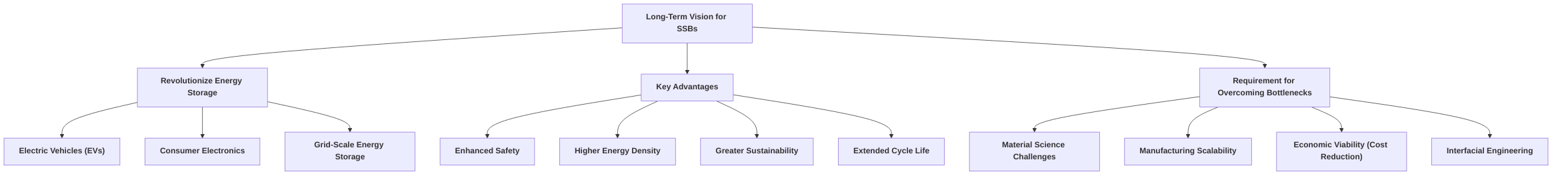

These proposed advantages could revolutionize various applications. Primarily, SSBs are envisioned to be transformative for electric vehicles (EVs), potentially enabling ranges exceeding 500 miles and doubling current driving distances, thereby addressing a key limitation of contemporary EVs compared to fossil fuel vehicles . Beyond EVs, the scope of applications is broad, extending to large-scale energy storage systems for grid stability and renewable energy integration, industrial equipment, drones, medical devices, consumer electronics, wearables, and aerospace . Miniaturized SSBs, such as those developed by ITEN, are particularly poised to transform energy management in electronic devices for the IoT sector, wearables, and healthcare, offering more sustainable and reliable alternatives .

While there is widespread optimism regarding SSBs, different perspectives emerge on their "long-term vision" and "projected role." Several papers consistently position SSBs as a sustainable energy solution for the future, a "technologically disruptive solution" for EVs and other applications, and crucial for supporting the transition to renewable energy sources and achieving global climate goals . The Faraday Institution, in particular, characterizes SSBs as "the technology of the 2030s but the research challenge of the 2020s," acknowledging their transformative potential while emphasizing the significant research and development hurdles that must be overcome in the near term for large-scale manufacturing to become feasible . This perspective suggests a balanced view, recognizing the high aspirations without underestimating the profound engineering challenges. Other sources, while equally enthusiastic about the potential, may implicitly suggest a more immediate readiness for widespread adoption than is currently realistic, given the complex material and manufacturing issues that persist . The overarching reason driving the shift towards solid-state technology is the urgent need for safer, more energy-dense, and longer-lasting energy storage solutions that can surpass the inherent limitations of conventional LIBs and meet the escalating demands of electrification and sustainable energy infrastructure.

Ultimately, the realization of these ambitious potentials for SSBs, whether in EVs, grid storage, or portable electronics, is critically dependent on overcoming the formidable challenges associated with their scalable manufacturing. Issues such as material selection, interface stability, and cost reduction are consistently highlighted as crucial advancements required for widespread adoption . The transition from laboratory-scale prototypes to mass production necessitates entirely new material architectures and fabrication techniques . Thus, while SSBs present a compelling vision for the future of energy storage, their market landscape and widespread integration are contingent upon surmounting these significant engineering and manufacturing bottlenecks.

2. Current Status and Market Landscape of Solid-State Batteries

The current market for solid-state batteries (SSBs) is characterized by a dynamic interplay of optimistic projections, ambitious commercialization timelines, and significant technological challenges. While the field broadly views SSBs as a groundbreaking innovation with the potential for transformative energy storage , a realistic assessment reveals a phased market entry dictated by application requirements and ongoing advancements.

The market is projected for substantial growth, from €50 million in 2022 to €269 million by 2028, reflecting a Compound Annual Growth Rate (CAGR) of 32.5%, driven by the demand for improved performance in terms of energy density, cycle life, and safety . Some forecasts anticipate a market value of $1.5 billion by 2025, with considerable demand expected by 2040, primarily from consumer electronics and the electric vehicle (EV) sector .

Commercialization timelines for SSBs show a range of projections. Early mass market adoption for consumer electronics and wearables was anticipated as early as 2022, and ITEN has announced full-scale production qualification for its Powency™ products by the second half of 2025, targeting wireless sensor applications and other high power density niches . For broader, large-scale applications, particularly EVs, projections generally converge between 2027 and 2030 . Toyota, a leader in SSB patent filings, aims for mass production of SSB-powered EVs by the mid-2020s, having planned a prototype unveiling at the 2020 Olympics . Similarly, Solid Power, in collaboration with BMW and Ford, targets vehicle SOP with 100Ah pouch cells in Q3 2022 . However, a more conservative outlook suggests significant volume market entry might not occur before 2030, recognizing the 5-6 year development timeline typically required for automotive implementation following proof of concept . Examples such as Bollore (polymer) and ProLogium (oxidic) are engaged in mass production, though their current performance may not yet match conventional liquid-based batteries . This suggests that while niche and early-stage commercialization is underway, widespread competitive adoption requires further maturation.

The industry landscape is populated by a diverse array of players, ranging from automotive giants like Toyota, Ford, General Motors, BMW, Honda, and Volkswagen, all investing significantly in SSB research, to specialized startups such as Solid Power, QuantumScape, ProLogium, Ionic Materials, and Ilika . These entities are pursuing various technological approaches, from high energy density cells (e.g., Solid Power aiming for 450 Wh/kg) to novel polymer electrolytes (e.g., Ionic Materials) and micro-batteries for specialized applications (e.g., Ilika) . Collaborative initiatives, such as the European ASTRABAT project, also emphasize the importance of cultivating internal expertise for next-generation cell production . The varied strategies, including targeting niche custom battery markets before broader mainstream adoption, highlight the nascent stage of the SSB industry and its ongoing strategic calibration .

The readiness of SSB technology for widespread commercialization is still evolving. Significant research and development are still needed to address fundamental challenges such as interfacial and mechanical stability . The transition from high-end custom markets to cost-sensitive mass markets, especially for EVs, remains a critical determinant of commercialization timelines . Wider roll-out into sectors like aviation is not anticipated until the 2040s, indicating a phased adoption based on application stringency .

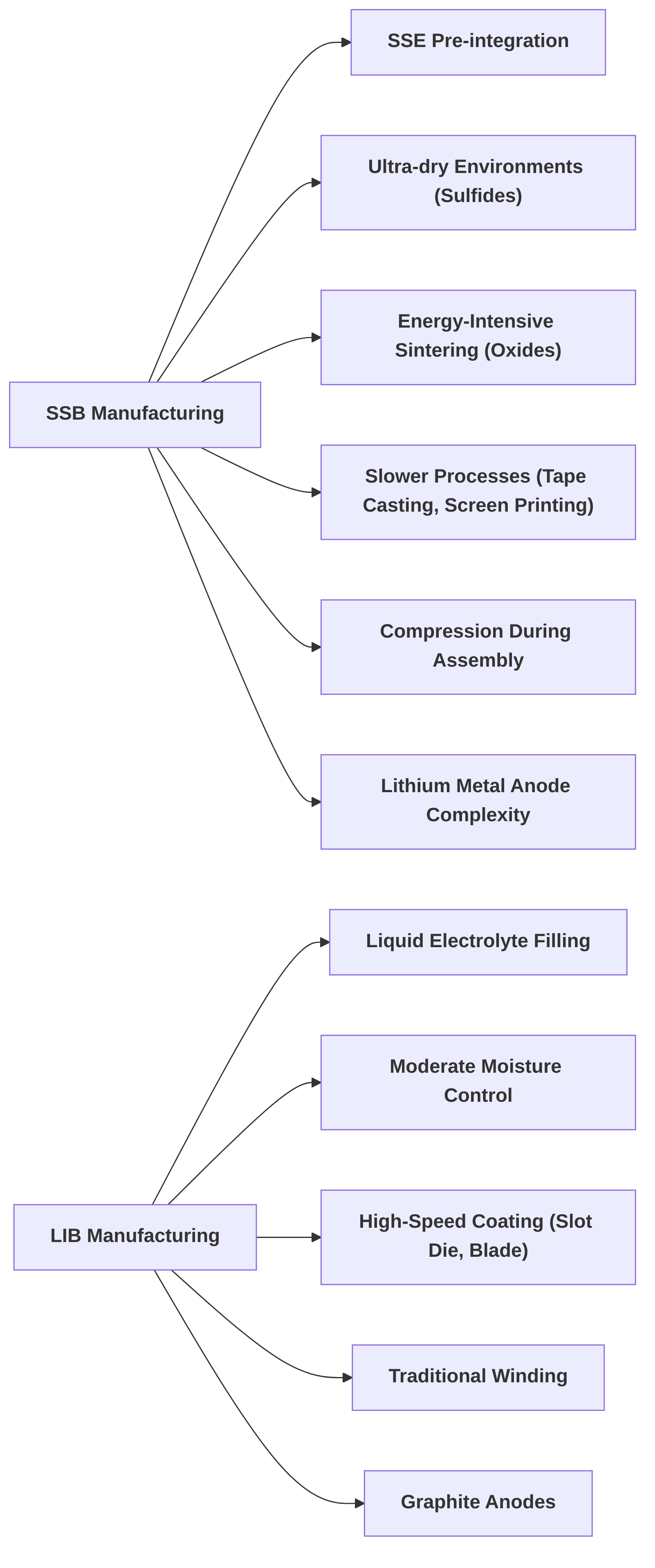

Crucially, the manufacturing approaches for SSBs present significant deviations from conventional lithium-ion battery (LIB) production, directly influencing potential cost and scalability. While some fundamental stages like cathode production can be similar, allowing for adaptation of existing LIB equipment , the core differences lie in the processing of solid electrolytes (SSEs) and lithium metal anodes. Unlike liquid electrolytes, SSEs must be pre-integrated, dictating distinct manufacturing pathways . Sulfide-based SSEs, for instance, demand ultra-dry environments (less than 1 ppm H₂O), adding complexity and cost to infrastructure, unlike LIBs which only require moderate moisture control . Oxide-based SSEs, while less moisture-sensitive, often require energy-intensive sintering processes .

Moreover, conventional high-speed LIB manufacturing processes, such as slot die or blade coating (25-50 m²/min, potentially 100 m²/min), are often replaced by slower methods like tape casting and screen printing for inorganic SSEs, significantly impacting throughput and per-unit costs . The highly viscous "inks" or slurries used in SSB production, incorporating dispersants and pore formers, further differentiate them from LIB slurries . A critical challenge unique to SSBs is ensuring robust interfacial contact between solid components, as poor ionic conductivity can arise from limited contact area and high interfacial resistance. This necessitates specific processing steps like compression during assembly for layered structures, which replaces the traditional "jelly roll" winding . The reliance on high-pressure testing in lab-scale SSBs highlights the need for advanced fabrication processes (e.g., wet slurry coating, dry electrode processes) that improve chemical compatibility without external pressure for scalable production . The integration of lithium metal anodes further introduces manufacturing complexities, such as lithium foil production, not present in current graphite-anode LIB manufacturing .

These inherent manufacturing differences directly lead to increased costs and scalability issues. The slower processing speeds and the need for specialized facilities (e.g., ultra-dry rooms) escalate infrastructure and operational expenses . The absence of a universally established process chain and the ongoing need to scale up less experienced methods from prototypes to multi-layered cell designs contribute to delays and significant R&D investments . Overcoming these manufacturing bottlenecks is paramount for the mass production of SSBs, a challenge that will be thoroughly explored in Chapter 3.

2.1 Commercialization Timelines and Projections

The commercialization of solid-state batteries (SSBs) is projected across various timelines, influenced by application segments and technological maturity. While some sources anticipate mass market adoption for consumer electronics and wearables as early as 2022 , broader large-scale commercial applications, particularly for electric vehicles (EVs), are generally forecasted between 2027 and 2030 . Notably, Toyota aimed for mass production of SSB-powered EVs from the mid-2020s, having planned to unveil a prototype at the 2020 Olympics . Similarly, ITEN announced that its Powency™ products were qualified for full-scale production in the second half of 2025, indicating early market readiness for certain applications .

Despite these optimistic projections, a more conservative outlook suggests that significant volume market entry might not occur before 2030 . This perspective is underpinned by the understanding that a development timeline of approximately 5-6 years is required for solid-state technologies to be implemented in vehicles following a valid proof of concept . For instance, while companies like Bollore (polymer) and ProLogium (oxidic) are engaged in mass production, their current performance is often considered inferior to conventional liquid-based batteries, highlighting the ongoing challenges in achieving competitive performance at scale .

Key factors influencing these timelines include the extensive research and development (R&D) progress still required. Issues such as interfacial and mechanical stability remain fundamental challenges that need to be addressed before series production can commence, as highlighted by the ASTRABAT cell type development . The transition from niche, high-end custom markets to cost-sensitive mass markets, particularly for EVs, is also a critical determinant of commercialization timelines . Niche applications, characterized by small battery sizes and lower barriers to entry, often serve as initial market opportunities before wider mainstream adoption . Looking further ahead, wider roll-out into sectors such as aviation is not anticipated until the 2040s, underscoring the phased commercialization approach based on the stringency of application requirements . The interplay between ongoing technological advancements and evolving market demand will critically determine the feasibility of meeting these ambitious timelines.

2.2 Key Industry Players and Their Commercialization Efforts

The landscape of solid-state battery (SSB) development is characterized by a diverse array of key players, including established automotive manufacturers, specialized startups, and research institutions, each pursuing distinct technological approaches and commercialization strategies . Their efforts are aimed at leveraging the custom battery market and achieving mass production.

Among the automotive giants, Toyota stands out as a leader in SSB patent filings and is actively collaborating with Panasonic on SSB research, with a stated objective of achieving electric vehicle (EV) mass production by the mid-2020s . This aggressive timeline positions Toyota as a frontrunner, indicating a strong commitment to integrating SSBs into mainstream automotive applications. Other significant players in the automotive sector, such as Ford, General Motors, BMW, Honda, and Volkswagen, are also engaged in dedicated SSB research programs, although their specific technological focuses and commercialization timelines are less explicitly detailed . Mercedes eCitaro, for instance, provides an early example of practical manufacturing experience with polymer electrolyte batteries in a vehicle .

In the realm of startups, Solid Power is advancing cells with high energy densities, reportedly around 450 Wh/kg . Similarly, QuantumScape has been noted for its work on pouch cell configurations and alternative anode manufacturing, where excess lithium is introduced on the cathode side . ProLogium has also established a joint venture for solid-state EV battery pack production . These companies are generally focusing on the high-energy density requirements of EVs, aligning with the broader industry trend towards improved range and performance.

Another notable startup, Ionic Materials, is specializing in novel solid-state polymer electrolytes designed for various battery chemistries and has partnered with A123 Systems for large-scale manufacturing slated for 2022 . This focus on polymer electrolytes suggests a strategy to leverage the manufacturing flexibility and potentially lower costs associated with these materials. Ilika, a UK-based company, has adopted a different approach by initially targeting micro-batteries for small, specialized applications, with plans to scale up for stationary power and EVs . Their reported potential for 1000 Wh/kg and a 10-year operating life indicates a strong competitive advantage in energy density and longevity, positioning them to enter broader markets once their technology matures.

ITEN is a leading innovator in Surface Mount Device (SMD) SSBs, with a strong customer base across various industries. Their technological approach involves leveraging nanomaterials and full-ceramic electrodes with a patented mesoporous structure . ITEN's focus on wearables, consumer, and healthcare applications, coupled with substantial funding and industry accolades, signifies a strategic entry into niche markets before potential broader expansion. This targeted approach allows for focused development and early commercialization in less demanding applications, which could then pave the way for high-volume markets.

The European ASTRABAT project, a network of experts and engineers, is dedicated to developing pouch cell prototypes. This collaborative effort highlights the importance for European manufacturers to cultivate internal expertise in next-generation cell production to maintain competitiveness in the EV market, despite acknowledging the inherent financial risks and the necessity of selecting appropriate machine manufacturers for upscaling . This initiative emphasizes a collective strategic approach to overcoming manufacturing challenges and fostering regional technological independence.

When cross-referencing these efforts with the general commercialization timelines, Toyota's mid-2020s target for EV mass production appears ambitious but attainable given their extensive R&D and patent leadership, potentially placing them ahead of some competitors. Ionic Materials' 2022 manufacturing target also positioned them as early movers in the polymer electrolyte space. Conversely, companies focusing on more complex or higher energy density chemistries may face longer development cycles. The varied approaches, from niche market entry to direct automotive integration, reflect the nascent stage of the SSB industry, where different players are calibrating their strategies based on technological readiness, market demand, and financial capacity . The collective efforts underscore a strong industry-wide push toward realizing the promise of SSBs, despite the significant engineering bottlenecks that remain.

2.3 Current SSB Manufacturing Approaches and Differences from Li-ion

The manufacturing of solid-state batteries (SSBs) shares some foundational principles with conventional lithium-ion batteries (LIBs) but introduces significant deviations, primarily driven by the replacement of liquid electrolytes with solid counterparts . Both LIBs and SSBs involve fundamental stages such as electrode production, cell assembly, and final packaging and testing . For instance, cathode production in SSBs can be largely similar to that in LIBs, involving the preparation of active materials, mixing with conductive additives and binders to form a slurry, and subsequent roll-to-roll coating onto current collectors . This overlap allows for the potential adaptation of existing LIB manufacturing equipment and experience, which could reduce investment costs and accelerate scaling for certain SSB components .

However, the core differences in SSB manufacturing arise from the unique properties and processing requirements of solid electrolytes (SSEs) and, often, lithium metal anodes. Unlike LIBs, where liquid electrolytes are filled post-assembly, SSBs require the pre-integration of solid layers during the stacking process . The materials used for SSEs—such as ceramics, sulfides, polymers, or oxides—dictate distinct manufacturing pathways. Sulfide-based electrolytes, for instance, are highly sensitive to moisture, often necessitating ultra-dry environments with less than 1 ppm H₂O, a significant contrast to the moderately moisture-sensitive processes for LIBs . Oxide-based SSEs, while less moisture-sensitive than sulfides, typically require energy-intensive sintering processes, which add complexity and cost .

The methods for fabricating these solid components also differ substantially. While LIB manufacturing employs high-speed solution-processed slurry preparation, coating (e.g., slot die, blade coating), drying, cutting, and calendaring, achieving working speeds of 25-50 m²/min (with potential for 100 m²/min), SSBs, particularly those with inorganic SSEs, often rely on slower processes like tape casting and screen printing, commonly used in solid oxide fuel cell (SOFC) production . The "inks" or slurries used in SSB production can also be more viscous due to the incorporation of dispersants and pore formers to control microstructure, further differentiating them from conventional LIB slurries .

A critical aspect entirely new to SSB production is the stringent requirement for robust interfacial contact between solid components. Unlike liquid electrolytes that inherently provide good contact, solid-solid interfaces in SSBs can suffer from poor ionic conductivity due to limited contact area and high interfacial resistance. This necessitates specific processing steps, such as compression during assembly to ensure good contact, especially for layered cell structures which replace the traditional "jelly roll" winding process due to the solid and often brittle nature of SSB components . Many lab-scale SSBs currently rely on high-pressure testing, a method not practical for large-scale applications, highlighting the need for advanced fabrication processes like wet slurry coating and dry electrode processes that improve chemical compatibility between binders, solvents, and SSEs without external pressure dependence .

The integration of lithium metal anodes in SSBs, while offering high energy density, introduces additional manufacturing complexities not present in current graphite-anode LIB manufacturing . The production of lithium foil through melting, extrusion, and calendaring, followed by lamination onto the cathode-electrolyte connection, is a distinct step in some SSB manufacturing flows .

These fundamental manufacturing differences directly translate into potential cost and scalability issues. The slower processing speeds of methods like tape casting compared to high-speed LIB coating significantly impact throughput and, consequently, per-unit costs . The need for specialized dry room facilities for moisture-sensitive materials adds to infrastructure costs . Furthermore, the lack of a universally established process chain and the ongoing research into optimized materials and techniques for SSBs mean that less experienced methods need to be developed and scaled up from prototypes to large multi-layered cell designs, which could lead to significant delays and increased investment in research and development . Overcoming these bottlenecks is crucial for realizing the mass production of SSBs, a topic that will be further explored in Chapter 3.

3. Engineering Bottlenecks in Scalable Solid-State Battery Manufacturing

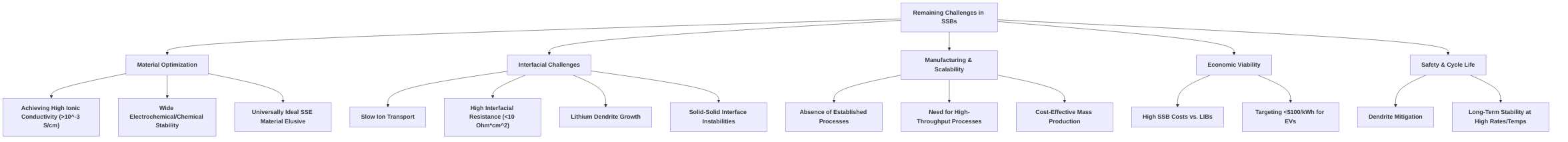

The widespread adoption of solid-state batteries (SSBs) is currently impeded by a confluence of intricate engineering bottlenecks, extending from fundamental material science challenges to complex manufacturing processes.

These bottlenecks collectively impact battery performance, safety, and ultimately, economic viability, presenting a critical juncture for scalable production . This section systematically categorizes and describes these impediments into material-specific issues, processing and assembly challenges, interfacial engineering complexities, and overarching economic and infrastructure limitations. A core underlying principle across many of these bottlenecks is the challenge of achieving uniformity and robust chemistry at the solid-solid interfaces.

Material-Specific Bottlenecks (Section 3.1) primarily revolve around the intrinsic properties and processing requirements of solid-state electrolytes (SSEs) and electrode materials. Key issues include the inherent trade-offs between ionic conductivity, chemical stability, mechanical properties, and manufacturability across different SSE classes (sulfide, oxide, polymer, and other emerging types) . For instance, while sulfides boast high ionic conductivity, their sensitivity to air and moisture necessitates costly dry-room environments and can lead to toxic gas formation, thereby increasing production complexity and cost . Oxides offer better environmental stability but are brittle, hard to process, and often require energy-intensive high-temperature sintering, impacting cost and scalability . Polymers, while processable, typically suffer from low room-temperature ionic conductivity . These material choices directly dictate raw material costs and the need for specialized equipment, intertwining with economic considerations. Furthermore, anode and cathode materials also present challenges, such as lithium metal's dendrite formation and volume expansion, which demand sophisticated stabilization strategies like coatings and composite architectures. Improving ionic conductivity, particularly at grain boundaries, remains a fundamental material challenge .

Processing and Assembly Bottlenecks (Section 3.2) stem from the radical departure of SSB manufacturing from conventional lithium-ion battery processes, primarily due to the reliance on meticulous solid-solid interfacial contact . This section delves into challenges across slurry preparation and coating, cell stack assembly, and forming and sintering techniques. Slurry preparation for SSBs is complicated by ultra-high viscosity and high solid content, leading to homogeneity issues, agglomerates, and trapped air bubbles that compromise interfacial contact and performance . Advanced mixing technologies are essential to address this. Cell stack assembly is prone to misalignment and non-uniform pressure, leading to high interfacial resistance and mechanical degradation, especially for brittle SSEs . Forming and sintering, particularly for ceramic SSEs, involve high-temperature, time-consuming processes that risk material degradation and significantly increase costs . The inherently slower processing speeds of these ceramic-based techniques compared to liquid electrolyte filling are a major hurdle for giga-scale production .

Interfacial Engineering Bottlenecks (Section 3.3) represent a critical and often overlapping challenge, rooted in the poor physical contact, chemical incompatibility, and resistive interphase formation at solid-solid interfaces . Electrode volume changes during cycling lead to contact loss and micro-cracking in brittle SSEs, while parasitic side reactions form resistive layers that impede ion transport . Unlike liquid electrolytes, solid interfaces lack self-healing capabilities, exacerbating dendrite growth and performance degradation . Current solutions, such as surface coatings, interlayers, and external pressure, offer partial mitigation but are limited. Critically, increasing interface pressure alone often fails to suppress lithium dendrite growth effectively, necessitating a paradigm shift towards novel material design and interface engineering that promotes uniform lithium deposition and actively suppresses dendrite nucleation, going beyond mere modulus adjustments . This directly links to material design principles outlined in Section 3.1.

Economic Bottlenecks and Infrastructure Limitations (Section 3.4) consolidate the cost drivers and infrastructure gaps hindering SSB industrialization. SSBs are significantly more expensive than conventional LIBs due to high raw material costs (e.g., lithium, lanthanum, zirconium) and the immaturity of production technologies . Specialized and costly equipment, such as gloveboxes for moisture-sensitive materials, further drives up per-unit costs and capital expenditure . Existing LIB manufacturing lines are not directly transferable, requiring substantial adaptation or new facilities, thereby increasing investment risks . Moreover, quality assurance is complex and costly due to material variability and nascent processing methods. The inherent complexity of manufacturing processes, including precise fabrication of SSEs and managing solid-solid interfaces, along with energy-intensive steps, translates directly into increased product costs . This section further emphasizes the need to integrate raw material costs and specialized equipment costs into a cohesive economic assessment.

In conclusion, overcoming these interconnected engineering bottlenecks requires a holistic approach. Material purity issues (Section 3.1), such as moisture sensitivity of sulfides, directly exacerbate processing challenges (Section 3.2), necessitating dry-room environments and specialized mixing equipment. These processing difficulties, in turn, contribute to poor interfacial uniformity and contact (Section 3.3), leading to high interfacial resistance and performance degradation. Furthermore, the specialized equipment and complex processes required for addressing these material and interfacial issues are significant cost drivers (Section 3.4). Therefore, a comprehensive strategy must critically compare the trade-offs in SSE material choices and processing methods to identify combinations that offer the most viable pathway to scalable and cost-effective manufacturing, considering raw material availability, process complexity, and safety . Future research must focus on synthesizing common underlying principles, such as issues with interface chemistry and uniformity, to develop robust solutions across these diverse challenges.

3.1 Material-Specific Bottlenecks

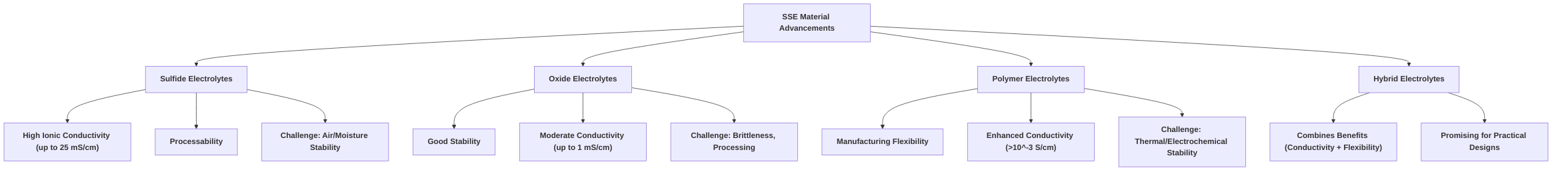

The scalability of solid-state battery (SSB) manufacturing is profoundly influenced by the intrinsic properties and processing requirements of their constituent materials, particularly solid-state electrolytes (SSEs) . Challenges in synthesis, purity, stability, and cost are prevalent across different SSE types, significantly affecting their compatibility with electrode materials and contributing to high interfacial resistance and degradation .

A primary material-specific bottleneck is the trade-off between ionic conductivity, stability, and manufacturability among various SSE classes. Sulfide-based electrolytes, such as lithium thiophosphates (LPS), argyrodites (LiPSX), and LGPS systems, generally exhibit high ionic conductivities, with some reaching up to 25 mS·cm⁻¹ . However, their poor air and moisture stability necessitates stringent manufacturing conditions, often requiring costly dry-room environments to prevent the formation of toxic H₂S gas, which substantially increases production costs and complexity . Furthermore, sulfide electrolytes can undergo parasitic reactions with lithium metal anodes without a protective layer and exhibit limited stability against cathode materials, hindering cycling performance .

In contrast, oxide-based electrolytes, such as NASICON-type (e.g., LATP), perovskite-type (e.g., LLTO), and garnet-type (e.g., LLZO) materials, offer superior stability in ambient air, simplifying manufacturing processes and enhancing safety . Their high hardness and deformation stability contribute to preventing dendrite formation . However, these ceramic-like materials are generally brittle and possess high elastic modulus, making them challenging to upscale and integrate into devices . Their ionic conductivity, while good (around 1 mS·cm⁻¹), is typically lower than that of sulfides at room temperature, and they are sensitive to CO and water, leading to poor interfacial lithiophilicity . Furthermore, manufacturing oxide SSEs, especially garnets like LLZO, is demanding due to their hardness and brittleness, often requiring high-temperature, energy-intensive processing, which significantly increases large-scale manufacturing costs .

Polymer electrolytes, while considered highly feasible for large-scale manufacturing due to their mechanical properties and processability, suffer from insufficient room-temperature ionic conductivity (around S·cm⁻¹) and limited thermal and electrochemical stability windows . This often necessitates elevated operating temperatures (e.g., >60°C for PEO) to achieve desirable performance, which limits their applicability in certain scenarios .

Other emerging SSE types also present unique challenges. Halide electrolytes offer high ionic conductivity and oxidation stability but are vulnerable to moisture and unstable with lithium metal anodes . Borohydride electrolytes show good ionic conductivity but are hampered by low thermal stability and hydrogen release issues, while anti-perovskite electrolytes, despite excellent stability against Li metal, require improved room-temperature ionic conductivity . Glassy solid-state electrolytes (GSEs) like LiPON are mechanically stable and dendrite-resistant but have low ionic conductivity and are largely limited to micro-battery applications due to deposition method constraints .

Material choices directly impact the overall manufacturability and cost. Raw material expenses, including elements like lithium, lanthanum, zirconium, and potentially germanium, contribute significantly to the total cost of SSBs . The need for specialized, costly equipment such as gloveboxes for moisture-sensitive materials further elevates per-unit costs, affecting scalability . Moreover, achieving competitive energy densities necessitates extremely thin electrolytes (below 40-225 µm), with slower processing speeds like aerosol deposition making these processes economically unviable for mass production .

Beyond electrolytes, anode materials, particularly lithium metal, present challenges such as dendrite formation, interfacial instability, and volumetric expansion during cycling, despite offering high energy densities . Cathode materials like NMC and LFP require stabilization against interfacial degradation, often achieved through nanoscale coatings and composite architectures, which adds complexity to manufacturing . The necessity of mixing active cathode material with a solid electrolyte (catholyte) further ensures ionic conductivity, creating additional processing steps .

Improving ionic conductivity, a primary bottleneck, requires a deeper understanding of ion transport mechanisms, particularly at interfaces like grain boundaries in polycrystalline SSEs . Current approaches like doping, nano-structuring, and interfacial engineering, along with controlling bulk phase conductivity through crystal structure characteristics, are crucial but demand further research . The ongoing quest for a flawless SSE that satisfies all criteria (conductivity, stability, cost, and processability) points towards composite SSEs as a promising research direction, leveraging the advantages of different material types to mitigate individual limitations . The choice of materials not only dictates performance but also fundamentally shapes the entire manufacturing ecosystem, impacting the feasibility and cost-effectiveness of large-scale SSB production.

3.2 Processing and Assembly Bottlenecks

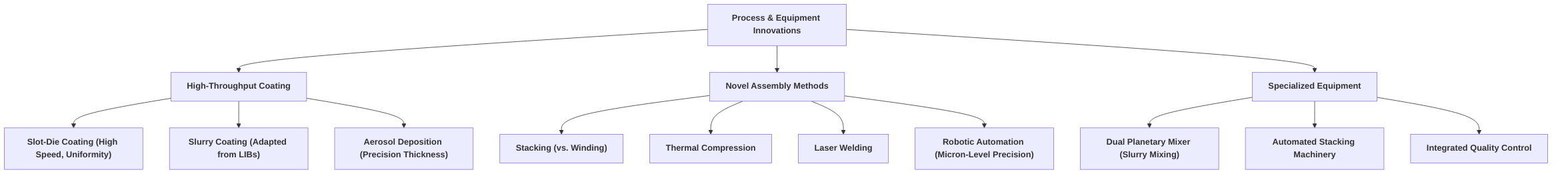

The manufacturing of solid-state batteries (SSBs) introduces unique processing and assembly challenges that significantly diverge from those encountered in conventional lithium-ion batteries, directly impacting scalability, cost, and overall performance . Unlike liquid electrolytes that readily infiltrate porous electrodes, SSBs rely on meticulous solid-solid interfacial contact, making precise material handling and assembly critical . This section comprehensively analyzes the engineering bottlenecks across key manufacturing stages: slurry preparation and coating, cell stack assembly and interfacial contact, and forming and sintering techniques.

A primary bottleneck arises in the slurry preparation and coating of electrode and electrolyte layers, particularly given the ultra-high viscosity and high solid content of SSB slurries, often exceeding 60% . Traditional mixing equipment frequently struggles to achieve molecular-level homogeneity, leading to critical defects such as agglomerates, inhomogeneities, sedimentation, and trapped air bubbles . These imperfections directly translate to poor interfacial contact and "dead zones" within the battery, severely compromising ionic conductivity, electrochemical performance, and safety . The introduction of advanced mixing technologies, such as dual planetary mixers, addresses these issues by providing the requisite torque and mixing efficiency, thereby enhancing slurry quality and uniformity, which is foundational for downstream processes and overall cell manufacturability and performance scalability . For sulfide solid electrolytes (SSEs), specific challenges include their sensitivity to polar solvents and moisture, necessitating the use of less polar or non-polar solvents and inert binders to ensure chemical stability and mechanical integrity . Subsequent coating techniques, such as slot-die coating and slurry coating, must ensure uniform layer thickness and prevent defects like cracks or pinholes. The choice of coating technique dictates throughput and defect rates, directly impacting manufacturing cost and overall battery quality, as higher resolution often comes at the expense of speed .

The cell stack assembly and interfacial contact represent another critical area of engineering complexity. Unlike liquid electrolytes that ensure intimate contact, SSBs rely on direct solid-solid interfaces, which are prone to high interfacial resistance if not meticulously managed . Assembly-induced defects, including misalignment, non-uniform pressure distribution, and insufficient contact, are pervasive and lead to reduced cycle life and increased impedance, severely affecting cell performance and safety . The rigidity of certain electrolytes, like garnet-based materials, exacerbates this issue, making robust contact with lithium metal anodes particularly challenging . Furthermore, chemical incompatibilities can lead to resistive layer formation, and mechanical stresses from electrode expansion during cycling can fracture brittle electrolytes, leading to performance degradation and safety concerns . Techniques such as thermal compression and the use of nanoscale interlayers are being explored to mitigate these issues by improving electrode-electrolyte adhesion and reducing impedance . While existing lithium-ion battery infrastructure might be adaptable for certain assembly steps, the delicate nature of solid components necessitates specialized dry-room robotics and precise grippers to prevent damage and short circuits, adding to the manufacturing complexity and cost .

Finally, forming and sintering techniques are pivotal for achieving desired material properties, porosity, and mechanical strength in SSEs, particularly for crystalline oxides, but they introduce significant bottlenecks for scalability and cost-effectiveness . Methods like physical vapor deposition (PVD) and chemical vapor deposition (CVD) offer homogeneous film growth but are typically expensive and time-consuming, posing considerable challenges for large-scale production . Tape casting and screen printing are promising for continuous, roll-to-roll processes, but they demand precise control over slurry formulation, debinding, and sintering to prevent defects and ensure material integrity . Conventional sintering, while common, requires high temperatures (e.g., 1200°C for LLZO) and extended durations, risking lithium loss and phase impurities, thereby increasing manufacturing costs and potentially reducing ionic conductivity . Advanced techniques like hot pressing, spark plasma sintering (SPS), and cold sintering offer faster densification or lower energy consumption but often present their own limitations, such as batch-based operations or challenges in achieving sufficient ionic conductivity . The fundamental trade-off between process parameters (temperature, time, energy) and their impact on material properties (density, ionic conductivity) and economic viability remains a critical challenge. The inherently slower processing speeds of these ceramic-based techniques, compared to the simple liquid electrolyte filling in conventional lithium-ion batteries, represent a significant bottleneck for achieving giga-scale production and cost parity .

In summary, the transition to scalable SSB manufacturing hinges on overcoming these multifaceted processing and assembly bottlenecks. Each stage, from slurry preparation to final cell assembly and sintering, introduces specific challenges that can lead to defects such as voids, delamination, and poor interfacial contact, directly impacting the battery's performance, safety, and ultimately, its manufacturing cost and scalability . Future research must focus on continuous and high-throughput methods that balance quality, speed, and cost-effectiveness, alongside innovations in materials and equipment to achieve robust and efficient SSB production at scale.

3.2.1 Slurry Preparation and Coating

The properties of slurry are paramount to the quality of the subsequent solid electrolyte layer and overall battery performance in solid-state battery (SSB) manufacturing. A critical challenge lies in achieving homogeneous mixing, controlling viscosity, and preventing issues such as agglomerates, inhomogeneities, sedimentation, and concentration gradients . These issues are particularly pronounced for sulfide materials, which are sensitive to polar solvents and moisture, necessitating the use of less polar or non-polar solvents in processing . While sulfide solid electrolytes (SSEs) offer excellent processability due to their inherent softness, their chemical instability with solvents and binders poses significant manufacturing hurdles . Aqueous processing, though environmentally and cost-effective, is generally unsuitable for SSE manufacturing due to surface alterations and lithium-ion loss .

The formulation of SSB electrode slurry presents a major processing bottleneck, primarily because it behaves as a non-Newtonian fluid characterized by ultra-high viscosity and high solid content, often exceeding 60% . Conventional mixers frequently lack the requisite torque to effectively homogenize such challenging slurries . Achieving molecular-level uniform distribution of active materials, solid electrolytes, and conductive agents is indispensable for ensuring the stability of solid-solid interfaces and optimal electrochemical performance . Furthermore, the presence of residual air bubbles within the slurry can lead to detrimental poor interfacial contact and "dead zones," thereby compromising battery performance and safety .

To address these challenges in slurry preparation, advanced mixing technologies are crucial. The dual planetary mixer, for instance, is designed to overcome the limitations of ordinary mixers by providing the necessary torque and mixing efficiency for high-viscosity, high-solid-content slurries . Such mixers are essential for achieving the molecular-level homogeneity required for stable solid-solid interfaces and improved electrochemical performance in SSBs . Binder selection is also critical for SSEs, requiring inert binders that provide mechanical strength and buffer particle expansion/contraction .

Regarding coating techniques, challenges include achieving uniform layer thickness, preventing defects such as cracks or pinholes, and ensuring good adhesion to substrates . Common roll-to-roll coating techniques mentioned include slot-die coating and slurry coating . Slot die coating is a promising roll-to-roll process for SSBs . While low-viscosity inks are preferred for high-throughput slot die coating in conventional Li-ion batteries, solid oxide fuel cells (SOFCs) often utilize more viscous feedstocks with pore formers, highlighting the impact of rheological properties on coating technique suitability . The choice of coating technique directly influences achievable coating speeds and uniformity, which are critical for scalability and cost-effectiveness. The trade-offs between different coating techniques in terms of resolution, speed, and defect formation significantly impact the scalability, cost, and overall quality of SSB manufacturing. Specifically, techniques that offer higher resolution may compromise on speed, while faster processes might be more prone to defect formation. Minimizing these defects is crucial, as they can lead to poor interfacial contact and "dead zones," thus negatively affecting battery performance and safety .

3.2.2 Cell Stack Assembly and Interfacial Contact

The assembly of solid-state batteries (SSBs) presents unique challenges compared to traditional lithium-ion batteries, primarily due to the nature of solid electrolytes and the imperative for robust solid-solid interfaces . Unlike liquid electrolytes that readily permeate porous electrodes to ensure intimate contact, SSBs rely on direct solid-solid contact, which can lead to significant interfacial resistance if not meticulously managed . This poor interfacial contact is a major bottleneck, directly impacting ionic conductivity and overall cell performance, contributing to reduced cycle life and increased impedance .

Assembly-induced defects, such as misalignment, non-uniform pressure distribution, and lack of intimate contact between layers, are critical concerns that affect both cell performance and safety . Achieving excellent contact between the solid-state electrolyte (SSE) and electrodes is crucial for optimal interface performance and ion transport . The rigidity of certain electrolytes, such as garnet-based materials, further exacerbates this challenge, making good contact with metallic lithium difficult and resulting in high interfacial resistance . Beyond physical contact, chemical incompatibility between materials can lead to the formation of resistive layers, while mechanical stress from electrode expansion and contraction during cycling can fracture brittle electrolytes, further deteriorating performance and safety .

Precise control over stacking and lamination processes is paramount to minimize interfacial resistance and prevent internal short circuits . Techniques like thermal compression are being explored to enhance electrode-electrolyte adhesion and reduce impedance, particularly for sulfidic and polymeric electrolytes, where lamination with pressure and heat is employed to reduce grain boundary and interfacial resistances . Innovations such as nanoscale Li₃PO₄ interlayers are also being developed to improve contact and reduce impedance . The integration of energy-dense anodes, such as lithium metal, introduces additional complexities that impact stacking, calendaring, and overall processing, making intimate contact even more crucial for effective ion transport and cell performance .

The scalability of assembly techniques is a significant consideration for mass production. While the existing infrastructure for lithium-ion cell production may be adaptable for solid-state cell assembly, packaging, and testing, the unique requirements of SSBs introduce new hurdles . The delicate nature of solid components makes winding difficult, necessitating precise positioning and alignment of sheets using specialized grippers, such as vacuum grippers, to prevent damage and avoid short circuits . The absence of a liquid electrolyte filling step in SSBs simplifies one aspect of production , and the anticipation of a shorter formation cycle with no need for degassing could potentially reduce production costs . However, the challenges associated with achieving uniform pressure distribution and maintaining intimate contact across multiple layers throughout both manufacturing and operational life continue to be major factors affecting scalability, cost, and ultimately, battery quality . These complexities require significant research into advanced manufacturing techniques to ensure high-quality, high-performance SSBs at a competitive cost.

3.2.3 Forming and Sintering Techniques

The scalable and cost-effective manufacturing of solid-state batteries (SSBs) critically depends on the judicious selection and optimization of forming and sintering techniques, which profoundly influence material properties, production throughput, and overall economic viability . Unlike traditional Li-ion battery manufacturing, which often involves simple electrolyte filling, ASSB production necessitates more complex processes such as high-temperature sintering or precision thin-film deposition to achieve the requisite solid-state interfaces .

For forming solid-state electrolytes (SSEs), particularly crystalline oxides, achieving high green density is paramount for subsequent sintering processes, while sulfide systems generally exhibit superior formability, facilitating better interfacial contact . Several forming techniques present distinct advantages and disadvantages for large-scale production. Thin-film SSEs can be fabricated via physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), sputtering, and sol-gel deposition, enabling homogeneous growth over substantial areas. However, these methods are often expensive and time-consuming, posing significant challenges for large-scale manufacturing .

Tape casting emerges as a highly promising scalable method for SSE layers, offering adaptability to roll-to-roll processes and co-sintering, which are critical for high-volume manufacturing. Nevertheless, successful implementation necessitates meticulous control over slurry formulation, debinding, and sintering conditions to ensure optimal material properties . Screen printing provides an effective means for applying thin coating layers and can be integrated with tape casting, enhancing manufacturing flexibility. Electrophoretic deposition (EPD), a technique with a high technology readiness level (TRL), is industrially employed for ceramic coatings and is suitable for compositions sensitive to aqueous environments. However, EPD is typically batch-based, which may limit its scalability for continuous large-scale production . Aerosol deposition is an ambient-temperature, low-cost method for producing dense films, but it requires a deposition chamber, and film properties are significantly influenced by powder morphology and post-annealing treatments. A key bottleneck for its scalability is the need for higher deposition rates . Solvent-free alternatives like hot powder rolling or dry pressing offer advantages in reducing cost and time for thick film fabrication . Additive manufacturing (AM) provides unparalleled flexibility and reduced material waste, offering potential for complex structures and cost reduction, yet challenges persist in achieving desirable surface quality, resolution, and mechanical properties for ceramic materials .

Sintering is a critical step for enhancing the mechanical strength of SSEs, reducing porosity, and minimizing grain boundary resistance, particularly for oxide SSEs . Conventional sintering, while widely used, demands high temperatures (e.g., 1200°C for LLZO) and extended processing times, which carries the risk of lithium loss and the formation of undesirable phase impurities, directly impacting ionic conductivity and overall battery performance . These high-temperature, energy-intensive processes contribute significantly to the high manufacturing costs of oxide SSEs .

To address these limitations, various advanced sintering techniques have been explored. Hot pressing and spark plasma sintering (SPS) offer accelerated densification compared to conventional methods. However, they are typically batch processes, which can limit throughput, and carry potential risks of contamination, affecting the final material purity and performance . Cold sintering, a low-temperature consolidation method, holds promise for reducing energy consumption but requires high pressures, and achieving sufficient ionic conductivity remains a significant challenge . Microwave sintering is highly energy-efficient but can induce thermal gradients within the material, potentially leading to non-uniform properties. Ultrafast high-temperature sintering (UHS) and flash sintering represent innovative approaches that enable rapid processing and mitigate lithium loss, though their application for SSEs is still in early development . For thin films, photonic and laser sintering offer rapid thermal processing, but their applicability to thicker films is limited, and they may require substrate heating .

The fundamental challenge across these forming and sintering techniques lies in the trade-off between process parameters (temperature, time, energy) and their impact on final material properties (density, ionic conductivity, microstructure) and economic viability. Achieving specific microstructures and preventing defects during these processes are critical to ensuring high-quality SSBs . The inherently slower processing speeds of these ceramic-based manufacturing techniques, compared to the simple electrolyte filling in conventional Li-ion battery production, present a significant bottleneck for mass production .

For scalable and cost-effective SSB manufacturing, the most promising combinations likely involve continuous forming methods like tape casting and screen printing, coupled with advanced sintering techniques that balance densification kinetics with energy efficiency and material integrity. Specifically, techniques that enable rapid, low-temperature processing while preserving lithium content and ensuring high ionic conductivity, such as advancements in cold sintering or more developed ultrafast sintering methods, will be crucial. These methods must overcome challenges related to temperature control, process time, energy consumption, and their direct impact on material properties and interfacial integrity to ensure both high quality and economic feasibility for large-scale SSB production .

3.3 Interfacial Engineering Bottlenecks

Interfacial issues represent a critical bottleneck in the widespread adoption of solid-state batteries (SSBs), significantly impacting performance metrics such as power density and cycle life . Unlike liquid electrolytes where the solid-electrolyte interphase (SEI) can exhibit self-healing properties, solid-solid interfaces are prone to poor physical contact, chemical incompatibility, and the formation of highly resistive interphases, which are less amenable to self-correction . These issues lead to high interfacial resistance, impeding ion transport and degrading overall cell performance and longevity .

A primary challenge lies in the dynamic nature of electrode materials during cycling. Volume changes within electrodes, particularly the anode, can lead to a loss of physical contact with the solid electrolyte, increasing impedance and potentially causing micro-cracks in the brittle solid electrolyte, thereby disrupting ion pathways and exacerbating performance decay . This issue is particularly pronounced at the interface between lithium metal anodes and solid electrolytes, which is notably fragile and susceptible to high contact resistance . Furthermore, chemical incompatibility between solid electrolytes and electrode materials can result in parasitic side reactions, forming resistive layers (e.g., Li₂CO₃ on lithium metal), which hinder ion and electron transport and contribute to reduced cycle life . For instance, sulfide-based electrolytes, while softer and capable of forming conformal contact, often exhibit narrow electrochemical stability and can react with both anodes and cathodes . Conversely, oxide-based SSBs can suffer from poor interfacial contact, resistive layers formed during thermal processing, electrochemical decomposition at high voltage, and space charge layers . The space-charge effect at the cathode interface is also known to impede charge flow .

Various strategies have been proposed to mitigate these interfacial challenges. Surface coatings are a prominent approach, with artificial SEI layers (e.g., LiF or Li₃N via Atomic Layer Deposition (ALD)) being developed to suppress dendrite growth and enhance ionic conductivity at the anode interface . Nanoscale Li₃PO₄ interlayers have also been used to reduce impedance . Protective layers for sulfide electrolytes are also critical to prevent parasitic reactions with lithium metal . Another strategy involves the application of external pressure to maintain physical contact between electrodes and electrolytes, thereby mitigating contact loss due to volume changes . Thermal compression techniques are also employed to enhance electrode-electrolyte adhesion . The development of composite electrodes incorporating conductive additives and carefully designed architectures (e.g., 3D host architectures) aims to homogenize lithium deposition and create efficient ion and electron pathways . Processes like sintering are noted to reduce interfacial resistance, particularly for oxide-based electrolytes .

Despite these efforts, current solutions face limitations. While external pressure can help mitigate contact loss, it is not always practically feasible in commercial applications . Conductive additives, often necessary for electron pathways in electrode composites, can degrade solid electrolytes, especially sulfides, creating a delicate balance between conductivity and stability . The rational design of interfacial coating layers with high ionic conductivity remains an area requiring further research . Fundamental research is still needed to fully resolve these intricate interfacial issues before scalable series production can be achieved .

A critical research direction stems from these limitations: the development of advanced interface engineering techniques that go beyond simple modulus increases to counter lithium dendrite growth . These techniques should focus on promoting uniform lithium deposition and actively suppressing dendrite nucleation, rather than merely relying on mechanical resistance to dendrite penetration. This involves designing interfaces that are not only ionically conductive and chemically stable but also possess tailored electrochemical properties to guide homogeneous lithium plating and stripping. Future research should explore novel interfacial materials and architectures that can intrinsically accommodate volume changes and prevent the formation of highly resistive interphases under operational conditions, ultimately leading to improved power density and extended cycle life in SSBs .

3.4 Economic Bottlenecks: Cost Drivers, Material Sourcing, and Quality Assurance Challenges

The mass production of solid-state batteries (SSBs) faces significant economic bottlenecks, with cost reduction identified as a key factor for industrialization . Currently, SSBs are estimated to be 2–3 times more expensive than conventional lithium-ion batteries (LIBs) . Projections indicate that by 2030, the manufacturing costs for all-solid-state batteries (ASSBs) could range from 90 per kWh, whereas LIBs are anticipated to reach $60 per kWh, highlighting a substantial economic gap that impedes large-scale adoption .

Several factors contribute to the high cost of SSBs. A primary driver is the cost of raw materials. Critical components such as lithium, cobalt, and nickel are substantial cost contributors, with cobalt alone accounting for approximately 60% of the value in some battery compositions . Beyond these, the high cost of specific solid electrolyte materials, including lithium, lanthanum, and zirconium, significantly elevates per-unit costs . The prices of some sulfide electrolytes, for instance, are currently far from industrial requirements, necessitating the development of more cost-effective alternatives like low-cost halide electrolytes with favorable atomic economy . The availability, scaling capacity, and price volatility of these material constituents are principal consequences of materials selection that govern manufacturing scalability, underscoring the interdisciplinary challenge of supply chain security and geopolitical factors .

Another significant cost driver stems from the immature production technologies and the inherent complexity of SSB manufacturing processes. These processes often require specialized and costly equipment, such as gloveboxes, particularly for handling air- and moisture-sensitive materials like certain sulfide electrolytes, further contributing to high per-unit costs . The energy-intensive processing required for oxide solid-state electrolytes also contributes to elevated manufacturing expenses . The current lack of commercial manufacturing processes for solid-state EV batteries makes direct cost benchmarking challenging . Higher complexity in production, including precise fabrication of solid electrolytes and managing solid-solid interfaces, along with time- and energy-consuming steps, translates directly into increased product costs . Furthermore, the need for new additives, doping, or coatings can negatively impact the total cell costs . Substantial capital investments are required for scaling cell manufacturing to meet growing demand, implying cost as a major bottleneck for European Li-ion cell manufacturers seeking to compete with Asian counterparts and develop know-how for next-generation cells like SSBs .

Process optimization and increased automation are crucial for reducing manufacturing costs. For example, processing speed is a key factor governing cost and scalability for giga-scale capacities. Slower manufacturing approaches necessitate higher capital investments, larger plants, and greater human resources. While coating costs for SSBs are currently higher than for LIBs across all process speeds, this margin decreases with increasing speed. At high coating speeds (e.g., 100 m/min), material costs become the dominant factor, whereas at low speeds (e.g., 1 m/min), annualized machine and building investment are the primary cost drivers . The potential for energy-dense anodes (e.g., silicon, lithium metal) and advanced cell architectures (e.g., bipolar designs) to offset cost differentials also presents a pathway for economic viability .

Quality assurance presents another significant challenge directly linked to manufacturing complexity and overall production cost. Implementing robust quality control measures, including defect detection, consistency in material properties, and performance validation, is particularly difficult for SSBs . This difficulty is exacerbated by the variability introduced by nascent, large-scale processing methods. The precise control of manufacturing process parameters is essential for achieving consistent material properties, thereby enhancing quality control. Developing non-destructive testing methods for quality assurance is of paramount importance to identify defects without compromising the integrity of the battery components. Innovations in processing, such as advanced mixing technologies, are critical to ensuring uniform material dispersion and consistent properties, which are fundamental to robust quality control and overall battery performance .

3.5 Equipment and Infrastructure Limitations

The scalable manufacturing of solid-state batteries (SSBs) faces significant hurdles related to equipment and infrastructure, largely stemming from the unique material properties and processing requirements of SSBs compared to conventional lithium-ion batteries (LIBs). A prevalent challenge identified across the literature is the insufficiency of existing LIB manufacturing lines, which are not directly transferable to SSB production without substantial modifications . This necessitates either significant adaptation of current infrastructure or the establishment of entirely new facilities, both of which incur high capital expenditure .

A primary specific need for SSB manufacturing is the requirement for specialized production environments, such as inert gas atmospheres or dry/clean rooms, particularly for processes involving highly reactive materials like lithium or sulfides . This contrasts with the less stringent atmospheric controls typically found in LIB manufacturing. Furthermore, specialized equipment is critical due to the unique characteristics of SSB components. For instance, conventional mixing equipment is often inadequate for handling the high viscosity and solid content of SSB slurries, thereby necessitating high-precision mixers capable of maintaining precise tolerances and stable operation during the transition from lab-scale to mass production . Other specialized equipment identified includes gloveboxes, ball mills, extruders, slot nozzle coaters, and sintering furnaces . The use of physical vapor deposition (PVD) methods for thin-film solid-state electrolytes (SSEs), while effective for small-scale applications, is limited in large-scale production due to prohibitive investment costs .

These equipment and infrastructure limitations profoundly impact the overall scalability and cost-effectiveness of SSB production. The immaturity of current production technologies, coupled with the need for specialized and costly equipment, contributes significantly to high per-unit costs for SSBs . The capital investment required for new, giga-scale manufacturing plants is substantially higher, and these plants are often slower in operation compared to their LIB counterparts . The current techniques are largely limited to micro-scale devices due to processing complexities, highlighting the need for extensive scale-up to overcome these limitations and achieve viable mass production . Furthermore, the challenges in industrialization plans underscore the need for developing entirely new manufacturing processes .

While there is a recognized need for new equipment and infrastructure, some papers suggest leveraging existing process experience and adapting certain Li-ion manufacturing steps to potentially save investment costs . However, the consensus indicates that direct transferability is unlikely without significant modifications . The transferability of competencies from LIB production is acknowledged, but this still necessitates the adaptation of technologies, implying that existing LIB infrastructure is not directly compatible without substantial upgrades or specialized tooling . Therefore, a balanced approach might involve adapting certain adaptable LIB processes while investing in entirely new specialized equipment and facilities for critical SSB-specific steps. The careful selection of appropriate commercial tools and machine manufacturers is crucial to de-risk the financial aspects of upscaling manufacturing chains .

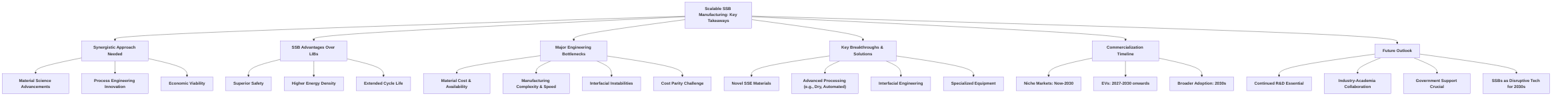

4. Breakthroughs and Progress in Scalable Manufacturing

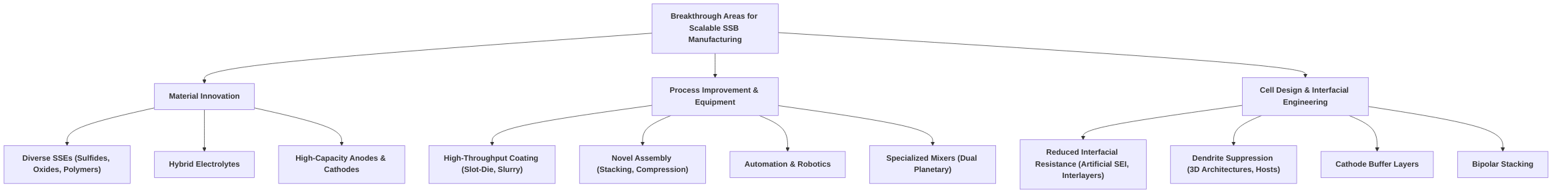

The transition to scalable manufacturing of solid-state batteries (SSBs) is being driven by significant breakthroughs and strategic mitigation efforts that directly address the bottlenecks identified in earlier sections.

These advancements span material innovation, process improvement, equipment development, and sophisticated cell design and interfacial engineering. Each solution offers unique mechanisms to enhance performance and manufacturability, moving the industry closer to high-volume production and commercial viability .

In material innovation, the development of diverse solid-state electrolytes (SSEs) such as sulfides, oxides, and polymers is paramount. Sulfide electrolytes, with their high room-temperature ionic conductivity (up to 25 mS·cm⁻¹), address the need for improved charge transfer, while their soft, paste-like consistency simplifies processing . Oxide electrolytes offer superior stability and conductivities up to 1 mS·cm⁻¹, directly tackling durability issues, although their brittleness poses processing challenges . Polymer electrolytes, known for their manufacturing flexibility, are being enhanced with additives to achieve competitive ionic conductivities ( S/cm), contributing to more adaptable production lines . Hybrid electrolytes combine the best features of inorganic and polymer materials, balancing high conductivity with mechanical flexibility, crucial for practical cell designs . Material innovations also extend to high-capacity lithium-metal anodes (3860 mAh/g) and novel cathode materials, addressing energy density and interfacial contact challenges .

Process improvements and equipment advancements are focused on enhancing uniformity, speed, and cost-effectiveness. High-throughput coating techniques like slot-die coating and slurry coating, adapted from lithium-ion battery (LIB) manufacturing, achieve high speeds (e.g., over 80 m/min for anodes) and thickness uniformity (2 μm), essential for roll-to-roll manufacturing and addressing issues like localized current density variations and dendrite formation . Novel assembly methods, such as stacking over traditional winding, along with thermal compression and laser welding, improve interfacial contact and mechanical integrity, crucial for brittle SSB components . Automation, including robotic systems, reduces manual handling and achieves micron-level precision, minimizing defects and breakage for delicate materials . Specialized equipment like the Yusheng Intelligent Dual Planetary Mixer tackles the critical slurry mixing bottleneck, improving material homogeneity and production throughput . These process and equipment innovations collectively address the need for high-quality, high-speed, and automated production, which are critical for cost-effective scaling and maintaining consistency.

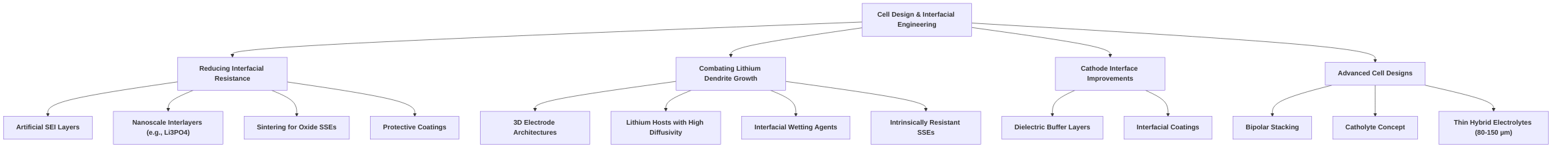

Cell design and interfacial engineering solutions are fundamental to overcoming resistance, enhancing cycle life, and bolstering safety. Strategies for reducing interfacial resistance include the use of artificial solid-electrolyte interphase (SEI) layers and nanoscale interlayers, such as Li₃PO₄, leading to improved cycle stability (over 80% capacity retention after 800 cycles) . To combat lithium dendrite growth, 3D electrode architectures, lithium hosts with high diffusivity, and interfacial wetting agents are being developed . For cathodes, dielectric buffer layers and interfacial coatings prevent side reactions and resistive layer formation, ensuring optimal ion and electron transport . Innovations in cell design, such as bipolar stacking and the "catholyte" concept, improve overall voltage and ionic conductivity within electrodes . These targeted solutions directly mitigate issues like high interfacial resistance, parasitic reactions, and dendrite formation, which are central to SSB manufacturing scalability and performance.

The impact of these innovations is evident in significant performance milestones. ITEN's solid-state battery, achieving an unprecedented 200C discharge rate and superior low-temperature performance, sets new benchmarks for power density and reliability . Broader SSB categories are reporting energy densities up to 500 Wh/kg and higher charging rates, with some prototypes exceeding 500 Wh/kg and demonstrating cycle stability over 800 cycles . These achievements translate into practical benefits like extended EV ranges and reduced charging times, showcasing progress towards overcoming performance limitations compared to traditional batteries .

Industry-led advancements and commercialization efforts are rapidly accelerating the adoption of SSBs. Major automotive OEMs and battery developers are forming strategic partnerships (e.g., Solid Power with BMW and Ford, Porsche with QuantumScape) and investing heavily in pilot productions and gigafactories, with commercialization anticipated between 2027 and 2030 . Companies like ITEN operate pilot lines capable of producing tens of millions of batteries annually, demonstrating tangible scalability . Lead is optimizing technology and processes for all-solid-state battery (ASSB) manufacturing, focusing on dry electrode processing and end-to-end automation . These efforts, coupled with initiatives to establish industry standards, signify a collective commitment to address manufacturing bottlenecks, de-risk financial investments, and ensure global competitiveness for SSBs . While challenges remain in achieving high current densities and robust low-temperature performance across all applications, the synergistic advancements in materials, processes, equipment, and cell design, bolstered by strong industry commitment, are paving the way for the mass production and widespread commercialization of solid-state batteries.

4.1 Advancements in Material Development

Significant advancements have been made in developing a diverse range of solid electrolyte materials, each presenting distinct properties, advantages, and manufacturing considerations critical for scalable solid-state battery production. These innovations directly address critical bottlenecks, particularly in improving ionic conductivity, enhancing interfacial stability, and reducing overall cost .

Among the prominent solid-state electrolyte (SSE) types, sulfide electrolytes stand out for their exceptional ionic conductivity at room temperature, with reported values as high as 25 mS·cm⁻¹ . Their relatively soft, paste-like consistency is advantageous for manufacturing, simplifying processing routes . However, a key challenge for sulfide electrolytes is their poor air stability and susceptibility to moisture, which can lead to significant cost issues and parasitic reactions during processing and operation . Strategies to mitigate these reactivity issues include applying protective coatings to the electrolytes or electrode materials .

Oxide electrolytes, particularly garnet oxides, offer good stability and high ionic conductivity, approaching that of liquid electrolytes, with reported values up to 1 mS·cm⁻¹ . Their inherent air stability is a significant advantage over sulfides . Nevertheless, oxide electrolytes present manufacturing challenges due to their high elastic modulus and brittleness, requiring focused research on practical processing routes for their integration into batteries . They can also exhibit sensitivity to CO₂ and water, albeit less so than sulfides .

Solid polymer electrolytes (SPEs), such as PEO-LiTFSI composites, offer manufacturing feasibility due to their flexibility and ease of processing . While their intrinsic ionic conductivity at room temperature has historically been lower compared to inorganic counterparts, advancements involve the incorporation of additives and inorganic nanofillers to enhance conductivity, achieving values greater than S/cm . The development of hybrid electrolytes, which combine the ionic conductivity of inorganic materials with the flexibility and interfacial contact of polymers, is a particularly promising avenue . These low-density hybrid electrolytes can achieve competitive energy densities at thicknesses of 80-150 µm, which is crucial for overall battery performance .

Beyond these primary categories, other promising SSEs include halide electrolytes, offering relatively high conductivity and stability, though they are vulnerable to moisture and interfacial instability . Borohydride electrolytes exhibit good conductivity but face challenges related to thermal stability and hydrogen release .

Material innovations extend beyond electrolytes to electrode materials. The integration of high-capacity lithium-metal anodes (3860 mAh/g) and high-voltage cathodes like NMC811 is crucial for achieving higher energy densities . Novel electrode materials designed for better interfacial contact with SSEs are under development, along with advanced binders and additives to facilitate cell fabrication . For instance, ITEN's technology utilizes patented mesoporous full-ceramic electrodes to significantly enhance specific surface area .

Improved material synthesis methods and processing techniques are fundamental to overcoming previous challenges in electrolyte performance and cost . Breakthroughs in synthesis routes focus on enhancing material purity, cost-effectiveness, and scalability . New processing techniques are vital for improving interface stability and ionic conductivity within the battery cell . For example, controlling the microstructure and interfaces of hybrid electrolytes during processing is emphasized to ensure optimal performance . Techniques such as doping, developing nano-scale structures, and interfacial engineering are actively pursued to enhance ionic conductivity and address solid-solid interface issues, which are critical for inhibiting lithium dendrite growth and ensuring long-term battery stability . Continued efforts are needed to bolster existing SSEs and develop innovative alternatives, alongside a deeper understanding of structure-to-property relationships through first-principles calculations and advanced characterization techniques .

4.2 Innovations in Manufacturing Processes and Equipment

Innovations in manufacturing processes and equipment are pivotal for overcoming critical bottlenecks in solid-state battery (SSB) production, particularly concerning uniformity, scalability, and cost-effectiveness. The field is actively developing and adapting advanced techniques to transition from laboratory-scale prototypes to high-throughput, industrial manufacturing. This section integrates discussions on advanced coating and deposition techniques, novel assembly and consolidation methods, and specialized equipment advancements, evaluating their impact on overall production efficiency and quality.

A key area of innovation lies in advanced coating and deposition techniques, which are crucial for achieving uniform, defect-free layers, particularly for solid-state electrolytes (SSEs) . High-throughput methods like slot-die coating are being extensively adopted for roll-to-roll manufacturing, offering significant speed advantages over traditional techniques and paving the way for cost-effective, large-scale production . While slot-die coating improves processing speed, achieving perfect thickness uniformity and minimizing defects remains a challenge . Techniques like aerosol deposition offer superior precision in electrolyte thickness control but currently face limitations in processing speed, highlighting a trade-off between precision and scalability . For electrode fabrication, slot-die and slurry coating, already proven in lithium-ion battery (LIB) manufacturing, are being adapted to achieve high speeds (e.g., over 80 m/min for anodes) with high thickness uniformity (±2 μm) for SSB composite electrodes, demonstrating significant progress in precision and speed . These techniques directly address challenges such as localized current density variations and dendrite formation by ensuring precise and uniform layer application, critical for enhanced battery performance and longevity .